Universal 6 axis robot

6-axis robot distributed by CNCVina in Vietnam is Universal Robots (UR) industrial robot product of the world’s leading cooperative robot manufacturer.

Vietnam is the sixth country in Southeast Asia to have Universal Robots. Worldwide, Universal robots are used in more than 31,000 production environments every day.

Universal Robots’ robotic arm effectively supports automation solutions in the manufacturing, assembly, inspection industry, etc. Currently in Vietnam, UR has provided robot arms for a number of industry enterprises plastic, cosmetics, electronic production and assembly, mechanical processing, automatic machine manufacturing …

UR Robots with automation solution is selected at a reasonable cost and businesses can recover capital after 2.5 years of use.

What's the special 6-axis Universal Robot compared to other industrial robot arms?

With 6-axis robot, Universal's cobot (robot), you don't have to worry about a cobot getting sick or quitting without warning, depressed mood or trauma when working. Or it takes too much time to learn a new process with the time and effort of training as a common worker.

The robot body has a compact and lightweight design, is lightweight, saves space with 6-axis arms designed to be minimalist, rounded, to work safely with people. Different from angled robotic arms, it often brings a "hard" feel.

Robot setup time is reduced from a few weeks to a few hours with UR robot.

Universal robots are used in more than 31,000 production environments every day.

6-axis robot, Universal's cobot (Corporate-robot), helps optimize investment costs, is flexible, safe and easy to use. Help you control your business better.

The application of Universal Robots

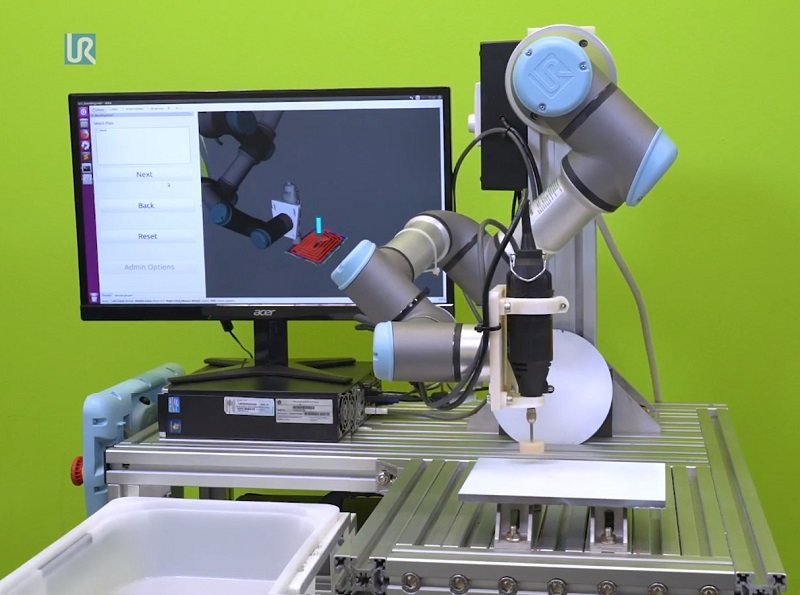

1. Application of robots to check product quality with collaborative robots (Cobot, corporate robot) - Quality inspection.

The image sensor system will be responsible for analyzing electronic products and components, mechanically transferred on conveyor belts, automatic conveyors. The cooperative robot (collaboration, Cobot) will position these components in the right position based on the data analyzed from the image sensor system. The robot then passes the product to the next stage of the production line.

2. Application of robots in automatic workpiece feeding system for lathes, CNC machining machines - CNC loading / unloading

For examples with the application of cobot UR10 for 2 CNC lathe systems (or grinder).

Cobot provides continuous workpieces for empty parts from the import trays.

Then pick and place the finished assembled components into the product trays.

Robots Universal can be applied to most processing and manufacturing machines that require mounting, unloading, continuous feeding. Robots help ensure accuracy and increase productivity remarkably in jobs: automatic workpiece feeding for lathes, milling machines, taking products out of plastic injection molding machines, automatic plastic feeding for injection molding machines ...

The robot arm can be rotated easily, at the same stage, it is possible to manipulate the finished product from the chuck and insert the new workpiece by rotating the joint 180 degrees.

To expand the robot's working space, with its light weight and compact size, the Universal 6-axis robot can be integrated into a sliding table. Easily move through CNC machine locations to perform workpiece feeding and product removal for CNC manufacturing.

Cobot helps CNC lathe system to operate stably and continuously 24/7 to create very high productivity.

3. Robot application for automatic packaging and cargo handling - Packaging & palletizing

Cobot UR3 helps pick up products and classify products at the same time on conveyor easily thanks to the ability to distinguish shapes and part colors by simple sensors. Brackets attach robots to a compact and easy assembly line.

Cobot automatically picks up the product box at the end of the conveyor belt and places it in the specified locations

Unlike traditional robots, cobot Universal can flexibly expand its premises and work space with a lifting mechanism below the stand. This structure helps increase the working height of cobot, stacking is higher but still ensures firm and safe rigidity.

4. Application of Universal robots to automatic assembly - Assembly

Cobot 6 axes UR3 used in assembly lines can automatically select components and parts on conveyors and assemble into complete assemblies (cylinder assemblies, printed circuit board assemblies ...). Including screw picking, Automatic screw feeder (screw screw) and screw mounting in assembly assembly. The head assembly can be a vacuum assembly, a pneumatic clamp head.

Robot 6 axes UR participates in almost all stages in the electronic assembly and assembly line, assembling motor vehicles, auto body painting, sheet metal, components, ...

Cobot uses tool converters, automatic grippers that are suitable for use with a variety of parts, components and products, handling multiple stages of assembly at the same time.

5. Application of Universal robot for polishing - Polishing

Collaborative robot UR5 is used for automatic polishing of various profiles for mechanical products. These profiles and contour can be installed for 6-axis robots manually. Or input from CAD models. ROS platform software helps to process 3D sensor data, reconstruct part of product surface and automatically create contour line, polished surface for parts.

Cobot Universal helps grinding and polishing products, metal mechanical parts easily (sanding, polishing). Minimize human participation and ensure uniformity in the quality of surface grinding and polishing.

6. Application of Universal robot for automatic glue application, automatic sealing and welding - Gluing, Dispensing & Welding

Robot UR5 helps to apply automatic glue to seal, seal, gluing according to the connection profile.

For parts that need 2-sides gluing, cobot can be integrated with the product rotating mechanism to apply the glue to the opposite side.

Universal Robot helps to flexibly switch, run fast and accurate contour sealing with similar quality glue, evenly glue on output products.

With automatic welding application, Universal 6-axis robot helps to weld, ultrasonic welding complex profiles in a hazardous environment for human health. Automatic welding technology by robot helps reduce concerns about labor safety and improve quality and productivity clearly. UR's most popular application is in the field of automobile, motorcycle and structural welding.

7. Combined with AGV self-propelled vehicles for factories - AGV Replenishment

AGV self-propelled vehicles combined with cobot UR10 help automate the transportation of product boxes and boxes between locations and production stages in your factory according to the desired scenario. 6-axis robots move safely by integrating 3rd party devices, such as SICK Microscan 3 safety scanners, to help robots move slowly and stop when detecting obstacles.

The coaxial 6-cobot UR product line

CNC distributes all Universal brand robots in Vietnam. Including cobot UR3 / UR3e, UR5 / UR5e, UR10 / UR10e corresponding to the ability to work with loads of 3-5-10 kg.

Refer to the product specifications of the 6-axis Universal robot arm in the table below and learn more at its homepage: Universal Robots.

|

Model |

UR3/UR3e |

UR5/UR5e |

UR10/UR10e |

|

Spec. |

|||

|

Reach |

500 mm / 19.7 ins |

850 mm / 33.5 ins |

1300 mm / 51.2 ins |

|

Payload |

3 kg / 6.6 lbs |

5 kg / 11 lbs |

10 kg / 22 lbs |

|

Footprint |

128 mm/5.03 ins |

149 mm/5.9 ins |

190 mm / 7.5 ins |

|

Weight |

11 kg / 24.3 lbs |

18,4 kg / 40.6 lbs |

28,9 kg / 63.7 lbs |

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese