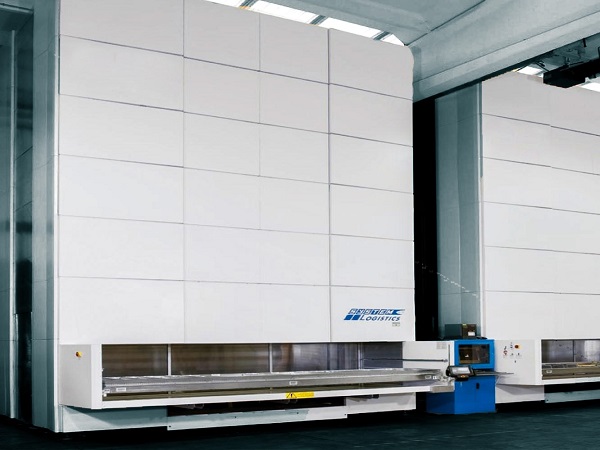

Smart warehouse module type

CNC-VINA is the representative of MODULA smart warehouse solution originating from Italy with its headquarters in Fiorano Modenese on a total area of more than 120,000 m2. Products are distributed in 25 countries worldwide.

Benefits of smart warehouses in factories

Saving box form in floor space.

High reliability guaranteed for many years of use

The tray size is suitable for many products.

Many breakthrough features to meet customer requirements.

Easy to use, multi-functional and flexible during use.

Smart warehouse module type is one of the world's leading modern automation solutions, which is used to bring great efficiency to the control of goods, warehousing and shipment at spare parts factories, Mechanical and electronic components, as well as control spare part serving production in modern mechanical manufacturing plants. Smart warehouse is an indispensable automation solution in future factory lines.

Structure of an smart warehouse module type

A smart warehouse includes:

Rear storage column

Trays

Center column

Lift platform

Workstation area

Front storage column

Maintenance ladder

Storage location

Operator interface

Control panel

Structure of an smart warehouse

A smart warehouse includes:

Square footage savings in floor space

Increased Productivity up to 3.5 times over static solutions

Increased item Protection with a fully enclosed storage system

Increased Ergonomics and Operators Safety

Increased Picking Accuracy

Improved Traceability

Avoid item damage

Space Savings

Example: On an area of 81 m2

there is the following configuration

Bays 58

Shelf Storage Capacity m2 0.4

Storage Levels Levels/bay 7

Bay Storage Capacity m2 2.9

Utilization Factor % 60

TOTAL STORAGE CAPACITY m2 100

Multiple units installation

External Units delivering through walls

Storage Quality

Full height light curtains located at the rear of each access opening location

for product protection and height measurement.

Lights on 25mm step

Product over height identification

Tray weight measurement system

Maximized travel speeds according to tray load

Ergonomics

Product is delivered at an ergonomic height

Heightbetween 0,7m and 1,05m from the ground level up

Nounwanted bending or reachingis required

External workstationallows for true top picking, optimum access for large or heavy items and for the use of overhead manipulators

Full height light curtains located at the front of each access opening location

Automatic sliding door available (as an option), located at the rear of the access opening location*

Physical Safety Barrier on the sides of each delivery bay

E-Stop button on the Copilot console

System Flexibility

Modular Unit Design:

Unit heights adjustability on 200 mm increments

Adaptable to future modifications

Allows for more flexible installations

Units can be installed within 100 mm of the usable ceiling height

Fixed Storage Locations

Fixed tray heights assigned for particular trays

Trays assigned to a specific location

Second delivery level flexibility 25mm increment step

Increase height capacity on first delivery level

Warehouse Management Software package ideal

and conventional storage methods

Complete control on inventory data

Static and dynamics storage configuration and management

User-friendly Interface

Able to integrate to any ERP system

Complete item traceability

Suitable to integrate existing inventory software systems

Real-time warehouse management via a PC Interface

Software based on a freeware SQL database server installed on a PC:

OnePC asserver required

Maxtwoclient PCs

Additionalclients with fee

WMS

Warehouse Management Software

User–Friendly Touch Screen Panel

Warehouse Management Software – Features

Secure Access: Password needed to login and access to the unit

Multiple Access Level

Operators

Supervisor (Advanced Operators)

Support(Maintenance& Set-Up)

Customizable restrictions

Protectionfor the wholeunit

Access for individualtrays

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese