Industrial robot for assembly

CNC-VINA provides customers with industrial robotic arms for assembly, inspection – automated solutions with robot arms for assembling electronic components, mechanical assembly robots, motor vehicles. With industrial robot arm in a smart factory, the production and assembly process will take place quickly and accurately with uniform product quality.

Helping customers significantly reduce production costs and improve output to create optimal competitive advantages. Along with loading conveyors, palletizing robots, AGV autonomous vehicles and intelligent warehouse systems, the production process is closed and optimized automatically.

Customers interested in industrial robots and automation solutions for smart factories please contact:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Hotline: 0915744664/0915740880

Email: Sales01@cncvina.com.vn / Sales03@cncvina.com.vn

An industrial robot is a system, a special machine used to perform a production task in industry. Industrial robots are automated, programmable and capable of moving on three or more axes.

A robot is a special machine programmed by a computer - capable of automatically (or semi-automatically) performing a series of complex and precise actions. Robots can be controlled using programmed commands or given by an external control device or an integrated processor. Robots can be built on the lines of a human form, but most robots are machines designed to perform a task regardless of their aesthetics.

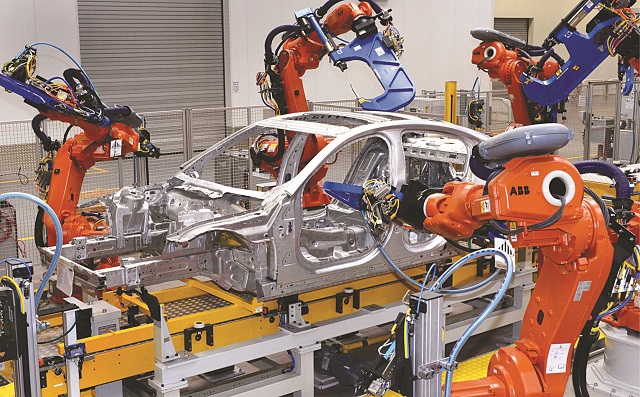

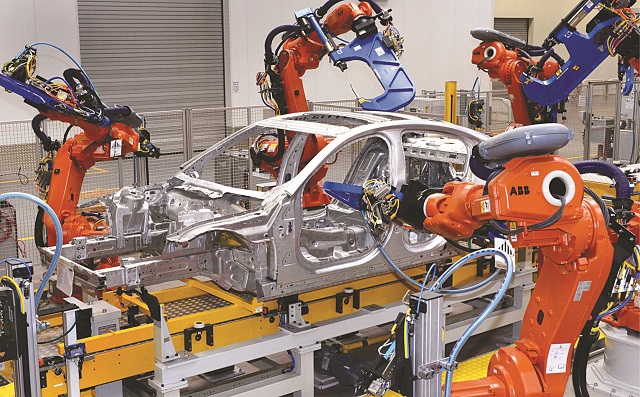

Industrial robots are usually shaped like a human arm with a rotating joint. They try to simulate simple to complex movements and perform the task in the same way as our arm. Industrial robot is commonly known by the name: Industrial robotic arm - Industrial robotic arm.

In the manufacturing industry alone, typical industrial robot applications include welding, painting, assembling, disassembly, pick & place, packaging and labeling, and palletizing robots, product testing and testing. All can be completed with high speed and precision. The industrial robot arm operates stably and steadily 24/7 in the toughest working conditions.

By 2020, an estimated 1.64 million industrial robots are in operation worldwide. They gradually become an important part of the production lines and assemblies in smart factories today.

Application of industrial robots in CNC-VINA assembly industry provided to customers

Inserting robot: Robot for insert electronic components

Inserting is the process of assembling components and products in an automated assembly line. It refers to component assembly, mainly to refer to products in the electronics industry. Because electronic products are often made up of many small components. Represented by the circuit board or control circuit of the device. Some operations such as: plug the pin of electronic components, plug electronic components on the PCB board ... are done quickly and accurately with the feed system from vibrating hopper, feeder or waiting tray available. Each inserting robot usually undertakes a task for one type of component to maximize its capacity.

Inserting Robot is used most by CNC-VINA in SMT line, UMC with Surface Mounting Machine. Assemble most electronic circuit board products for printers, telephone circuits, TVs and other electronic equipment.

Advantages of using robots for the inserting process in the assembly line:

The speed of plugging components onto the circuit board is fast, productivity is many times higher than traditional workers.

The assembled robot works 24 hours a day for long periods of time without rest

Outstanding work quality with high accuracy and reliability

Safe in operation, easy to expand into systems

Easily integrate with related peripherals and synchronize data onto the production management system, smart warehouse of the line.

Robots assemble electronic and mechanical components

Mechanical and electronic components assembling robots operating with feeder systems put components or components of the product within reach of the robot with the pick and place position (pick & place). pre-programmed. Main products are loudspeaker clusters, phone screens, TVs, printer circuit boards, motors, cars, motorcycles ...

In essence, assembly robots have the same principle of operation that is not much different from inserting robots. But assembled robots often have slower working speeds due to larger, heavier, variety of products and complex movements that require greater precision.

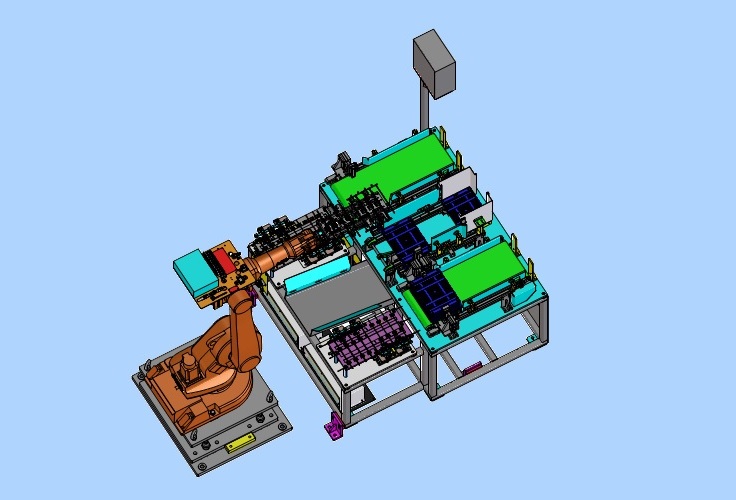

Printer assembly robotics - automation solution provided by CNC-VINA to customers

Refer to the CNC-VINA products provided to customers:

CIS printer assembly line automatically

Automatic assembly line integrates robot to stack printer parts

Automatic production line

To promote the capacity of electronic and mechanical assembly robots, people often arrange feed vibrating funnels to help classify and arrange input components in a regular manner in the correct position. The industrial robot arm will pick-and-drop into the assembly position according to the pre-programmed scenario. Sometimes, the robot is also integrated with an automatic screwdriver, a pneumatic, electric and hydraulic bolt gun with the feature to pick up screws, bolts, put into position and screw, tighten with preset force. Provide uniform assembly quality.

Product inspection robot

After fabrication and assembly process, all products must be checked their specifications, the criteria are given to assess the product PASS / FAIL. Tests can be computational measurements that give results that need to be accurate and fast. Sometimes, with humans, the inspection becomes boring and easily leads to subjectivity and errors. Especially simple tests in mass production.

The inspection robot appears to assist or replace humans, providing higher productivity with ideal accuracy.

The application of measuring and testing the product by robot can include: visual test, measuring the geometric size (Measuring), testing durability, friction (Testing)...has been CNC- VINA provides to customers in the electronics, mechanical processing, manufacturing and assembling cars and motorcycles. The test robot is integrated with measuring and calculating equipment and giving results or giving orders to the processing robot such as picking up NG products, sorting output products. This stage can be combined with Auto guided vehicle AGV to transport products in / out of the warehouse.

With 13 years of experience in the automation industry and projects using robots to assemble electronic and mechanical components, CNC-VINA provides customers with an automation solution with an industrial robotic arm that brings quality outstanding assembly and productivity.

Experienced technical team always updates technology, providing customers with optimal and flexible automatic assembly solutions using industrial robots in modern production lines.

We supply industrial robots in high-performance, high-precision manufacturing areas including:

Electricity - electronics

Mechanical assembly, automobile and motorcycle industry

Food industry

Medical equipment industry

Customers wishing to consult, design, manufacture and install automatic lines and automation solutions with industrial robots please refer to our typical projects below and contact us for support.

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Factory: Song Cung industrial site, Dong Thap commune, Dan Phuong district, City. Hanoi Vietnam

Phone: +84.915 74 4664 / +84.915 74 0880 Fax: +84.24.37805007

Website: www.cncvina.com.vn; www.maytudong.com.vn; www.cncvina.net

Email: Sales01@cncvina.com.vn / Sales03@cncvina.com.vn

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese