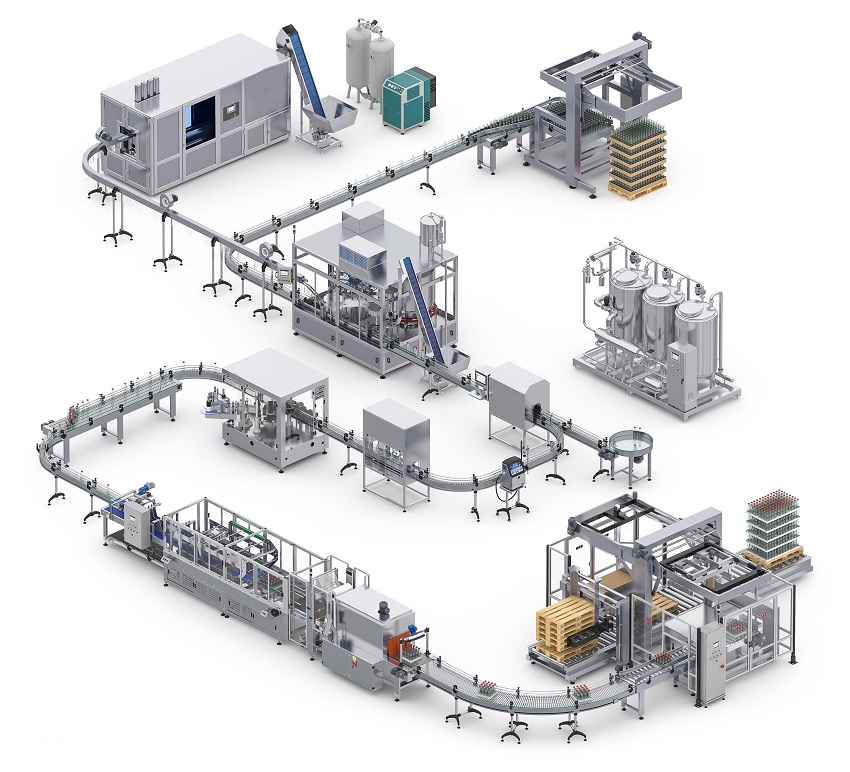

Filling-labeling-packaging line

Automatic filling-labeling and packaging lines for plastic bottles and glass bottles increase productivity, improve product quality and reduce production and packaging costs. The automatic bottling and filling line is applicable to a wide range of products in the food, beverage, medical, pharmaceutical and chemical industries in Vietnam.

Customers who have a demand for packaging machinery and automatic solutions please contact us for support:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Hotline: 0915744664 | 0915740880

Email: Sales01@cncvina.com.vn | Sales03@cncvina.com.vn

CNC-VINA Filling-Labeling-Packaging line is an automatic or semi-automatic product packaging line system consisting of some or all of the following machines: filling machine, labeling machine, machine bottle capping, shrink film machine, carton sealer, strapping machine, pallet wrapping machine...are connected to industrial conveyor system, printer, barcode reader, production management with high automation, providing outstanding productivity, minimizing labor at the highest level.

Filling - labeling - packaging line used for packaging applications, bottle filling: PET plastic, glass bottles for different types of beverages: purified water, drinks, cosmetic, chemicals...depending on your love demand of customers.

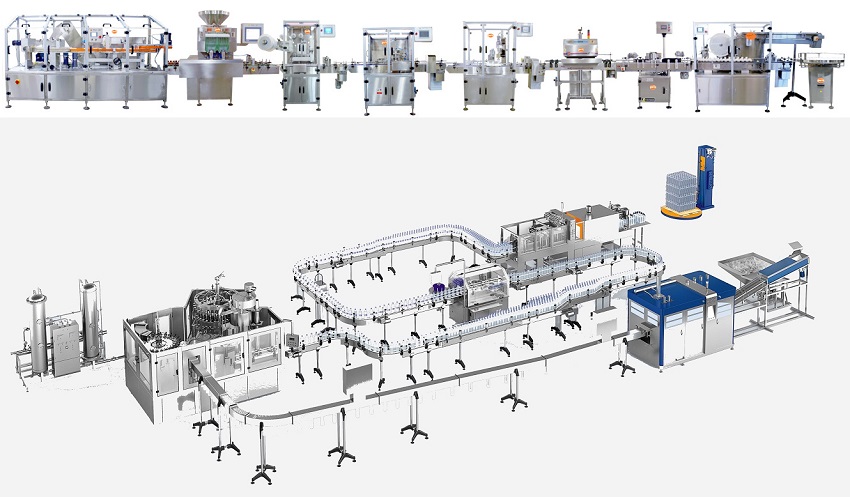

A state-of-the-art filling and bottling line for glass bottles

Popular filling-labeling-packaging line

The automatic bottling line is an automatic system integrating all stages

The stages of CLEANING-FILLING-CAPPING-LABELING-SHRINKING-CARTON SEALER-STRAPPING- WRAPPING equipped with modern technology.

The stages in the line are almost completely automated to ensure high accuracy and productivity.

Applications for: purified water bottles, wine bottles, alcoholic beverages, carbonated drinks, fruit juices, pharmaceuticals, chemicals, food ...

Common stages of a bottling line include:

Erect, feed bottles by conveyor system, feeder from bottle-shell containers or fully automatically with automatic pick-up mechanism. Usually the feeding of bottles into the feeder system is done manually by the manipulation of the worker.

AUTOMATIC BOTTLE CLEANING

The bottle washing is conducted with water (hot water) to sterilize the bottle, cleaning. After being washed, the bottles are passed through a dryer or blower drying system to dry. With disposable plastic bottles, the rinse step is eliminated. Purified water bottles will be fed directly to the feeder system to the filling nozzles.

Normally, with a large capacity line, customers use a 3 in 1: washing - filling - capping the lid to help the filling process close with high capacity, ensuring food hygiene and safety.

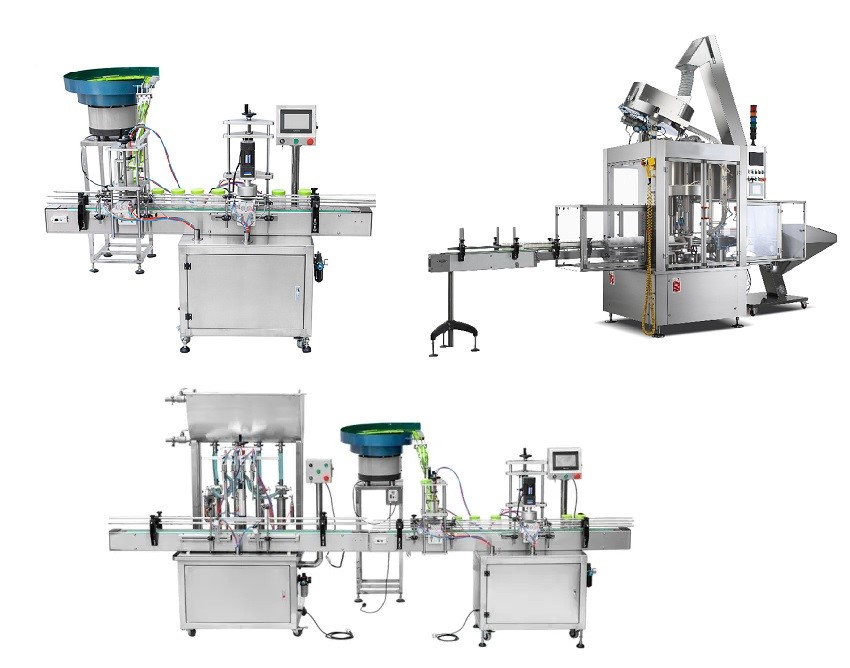

AUTOMATIC FILLING

Filling machine with rotary table: 8-10-16-20-40… at the same time depending on the required capacity and capacity of the bottle. It is also possible to fill in line, bottles are conveyed in a straight line conveyor and filled at the same time to enough capacity with a quantitative filling tip. Or pouring many times, each time through a nozzle with a certain volume. Allow the bottle to be filled with the required capacity after exiting the last linear filling.

With filling lines that do not require high automation and low yields, the bottles can be supplied with a conveyor attached to a 1-2 head filling machine. Bottles are placed in and lifted out of the filling position by a worker or a short conveyor with a sufficient amount of shells for low filling capacity.

There are many automatic filling options including:

+ Filling with a fixed capacity for a bottle with an exact capacity.

+ Filling capacity can be flexibly changed.

+ Filling capacity ranges: 100-500ml, 500-1000ml, 1000-2000ml, 2000-5000ml ...

Filling line status control, filling quantity, capacity, filling capacity adjustment are all integrated and calibrated on the HMI control screen with a friendly, easy-to-operate interface.

AUTO CAPPING MACHINE

The bottle capping machine using the 2, 3, 4 roller cap screwing helps ensure accuracy and capacity to meet the filling stage. Most plastic and glass bottles, jars for purified water, soft drinks, and beverage products use threaded plastic bottle caps. We also provide cork solution for glass bottles containing alcoholic beverages such as wine, white wine using wick (wooden cap). With some types of purified water and beverage bottles, the bottle cap will be sealed after being screwed on by the Shrink Tunnel.

The bottle cap supply process can be done by the worker to save costs. The bottle cap can also be fed automatically by a bowl feeder integrated with the screw driver.

There are 2 popular types of bottle label that are plastic film labels and label bottles with paper labels, decal labels, sticker.

SLEEVE LABELING

Normally, filtered water, plastic and glass bottles are labeled with plastic film because of the special shape of the bottle. With plastic film labels (plastic film), bottle labeling process is done by plastic film launcher - Sleeve labelling. The machine is designed to release the label according to the shape of the bottle. Cut the label from the label roll and automatically eject the label onto the bottle neck, bottle body (the exact location needs to be labeled according to customer requirements).

+ AUTO SHRINK

Thanks to the shrink film machine with the heating chamber, the label is heat shrink and firmly attached to the bottle body. The plastic film shrinking machine for plastic bottles and glass bottles is easily adjusted for temperature and hot air flow depending on the type of bottle label to help the film shrink quickly, firmly and beautiful without affecting the quality of the bottle and product side. in.

+ ROUND BOTTLE LABELING WITH DECAL, STICKER LABEL

The method of labeling bottles with decal paper labels, this sticker is used when PE, PET, and glass bottles have a smooth shape, the surface of the labeling does not change. With this method of labeling, bottles only need to run through the roller system of labels and be rotated to label the correct position on the bottle. Labeling decal, sticker paper label does not need shrink film as with plastic labels, plastic film labels.

The construction of plain paper labeling machine includes:

The bottle separator cluster (product) when the bottle enters the machine to reach the sealing position should be spaced between two adjacent bottles to ensure cycle time and smooth system operation.

The screw cylinder assembly for labeling includes the rotating motor and the control cylinder

Automatic label feed cluster: used step motor motor and sensor sensor for label stop positions, input product sensor for precise label feed and stop .. The intelligent control system calculates and adjusts function clusters concurrently for sequential and precise bottle labeling.

Error control system with sensor, sensor detects when there is no bottle, out of label, torn label ...minimizes errors.

The control cabinet is neatly arranged on the machine, PLC equipment, servo, drive, inverter, sensor, touch screen imported from brands Schneider, Panasonic, Delta ... imported from Taiwan, EU Japan, Australia, China help to stabilize operation, improve quality and accuracy when labeling.

Touch screen HMI controls intuitive, friendly interface and easy to operate and operate.

The mold correction system for bottles helps to change the label according to different products, different positions on the product.

For some square and flat bottle products with a more special way of labeling, the machine's labeling mechanisms will be customized to ensure the label is attached at the correct position on the bottle, without creasing and adhesion . Flat labeling machines, square bottle labeling machines, flat bottle labeling machines, single-sided, double-sided labeling machines, flat labeling machines, horizontal labeling machines ...

For most types of filtered water bottles, the product after labeling, screwing the cap and shrinking the cap is transferred immediately through the packaging process on the carton sealing machine. Soft drink bottles, beverages are often packed in blocks before being cartoned. Packaging of bottles in block with shrink film makes it convenient for transportation and sales.

BLOCK – SHRINK TUNNEL

The bottles are packed in blocks of 6, 10, 20 bottles ... depending on the packing's specifications and the size and weight of the bottles. Bottles after the process of shrinking the label film, automatically labeled will be followed by the conveyor to the waiting position and quickly gathered into blocks. The blocks (which can be packed into a tray) are packed using a packing and sealer.

CARTON SEALER

This is the process of packing the product on the lid folding and sealing machine. If the bottles, after being labeled, are not packed in blocks, they will be sorted into cartons either manually by the workers or automatically by the pullers. Cartons are usually opened and pre-placed into the glazing machine (after loading the product). It is also possible to automate the pre-installed case opener. The carton is then folded and glued to the top or bottom and top.

STRAPPING MACHINE

The plastic strapping stage for the finished product carton with carton strapping machine ensures secure storage and transportation.

The strapping machine works on a range of belt sizes and thickness suitable for a variety of barrels with different sizes and weights: Plastic belt 9-15, thickness 0.5-1.1mm. The strapping machine supports horizontal carton strapping, flexible vertical carton. Strapping takes only a few seconds at 20 ~ 30 belts / min. So the strapping yields are very large.

PALLET –WRAPPING MACHINE

Products after being palletized waiting for storage or shipped to customers will be wrapped with an automatic film wrap machine to preserve products during transportation.

Depending on the size and weight of the pallet, the package will be film wrapped on a turntable or support conveyor.

Automatic filling and bottling line helps to replace human, improve product quality, increase productivity and reduce production costs.

Customers wishing to find out and order an automatic filling line please contact support:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Factory: Song Cung industrial site, Dong Thap commune, Dan Phuong district, City. Hanoi Vietnam

Phone: +84.915 74 4 664 / +84.915. 74 0880

Website: www.cncvina.com.vn; www.maytudong.com.vn; www.cncvina.net

Email: Sales01@cncvina.com.vn | Sales03@cncvina.com.vn

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese