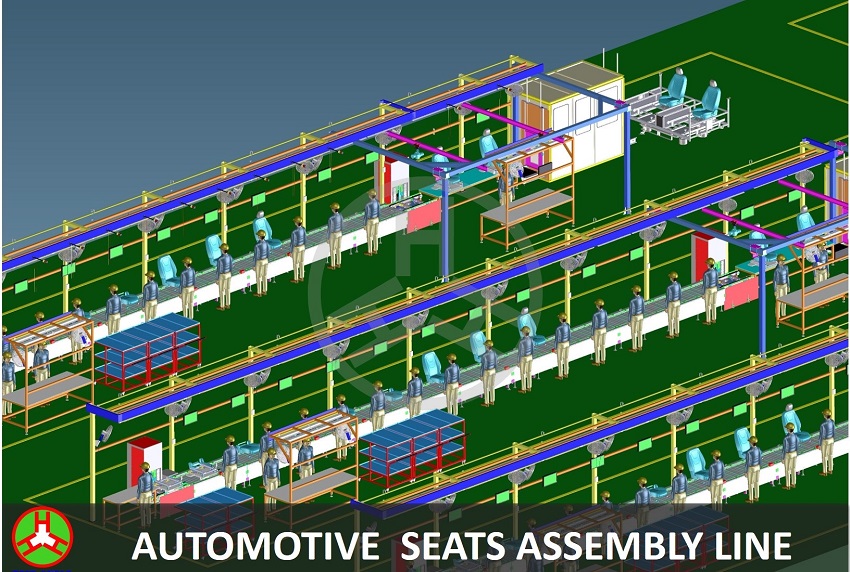

Automotive seat assembly line

Automotive seat assembly line provided by CNC-VINA to customers to meet the needs of manufacturing and assembling complete car seats with a capacity of up to 180 sets / day.

The production line is a turnkey turnkey project with total solution designed, fabricated, installed, programmed and operated by CNC-VINA engineers. Assembling, testing, and manufacturing operations are at a high level of automation. Bring satisfaction to customers.

Please contact us for more advice on assembly lines and automation solutions for your products:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Hotline: 0915744664 | 0915740880

Email: Sales01@cncvina.com.vn | Sales03@cncvina.com.vn

The automotive seat assembly line is one of the assembly-inspection lines in the automotive and motorcycle manufacturing and assembly industry that CNC-VINA has provided to domestic customers for many years.

In the domestic automobile industry, the demand for localization is increasing. In recent years, the birth and strong development of car manufacturer Vinfast together with domestic automobile manufacturers and assemblers such as Kia, Hyundai, Ford...has contributed to expanding and improving. the scale of the Vietnamese automobile industry.

CNC-VINA provides customers with comprehensive solutions in the field of manufacturing and assembling automobiles and motorcycles, including the seat assembly line.

Join us to learn about a car seat assembly line that has been designed, manufactured and installed for domestic customers by 2020.

[toc heading_levels="1,2,3,4"]

General introduction to the car seat assembly line

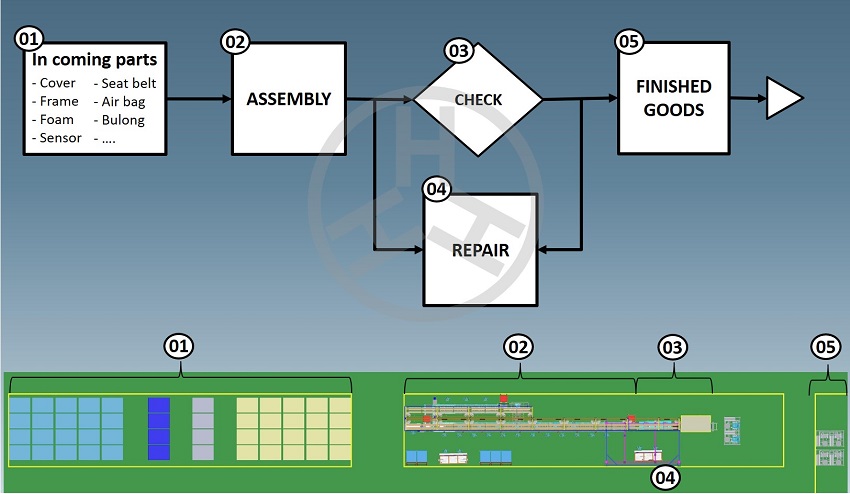

The car seat assembly line carries out the assembly process of a car seat complete with: seat face, back, headrest, armrest, lift, adjusting button, airbag, seat belt and other accessories.

The car seat covers are transported to the material stockpile from the Car Seat Cover Sewing Line - which also provided by CNC-VINA for the customer.

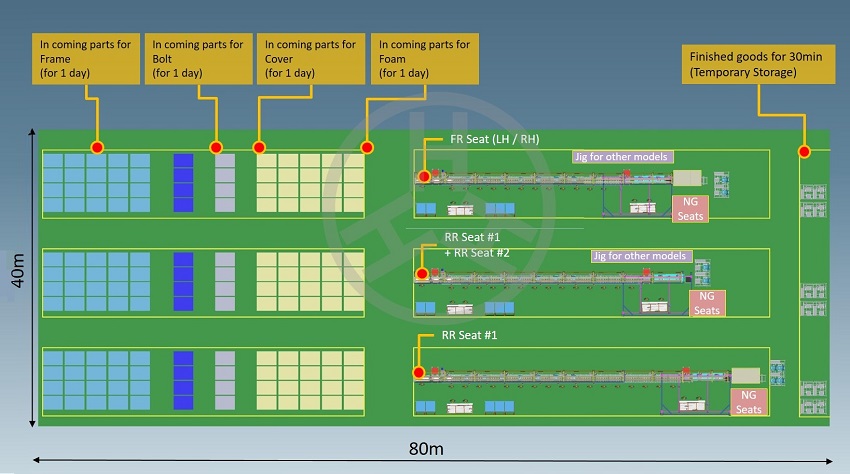

The automotive seat assembly line is designed and installed on a factory premises of 3000m square, with a capacity of 180 sets / day, the number of personnel about 60 people participating in the stages: material supply, assembly, QC , product repair, and finished product management.

Main stages in an automobile seat assembly line

In order to assemble a complete car seat, the assembly-inspection process must go through nearly 50 consecutive stages including assembly and testing, measuring parameters.

The main stages of assembly of car seats can be mentioned:

- Shoot pins and insert the seat cover onto the sponge (with sitting surfaces, armrests, headrests respectively)

- Install seat belt

- Attach the seat frame to the body

- Assemble seat legs

- Install locks, hinges

- Install the handle

- Install armrest, headrest

- Functional testing

- steam

- Test noise level

The line is fabricated at CNC-VINA factory to combine construction and installation at the customer's factory, test run and test within 12 weeks.

The main functional blocks of an automobile seat assembly line

- Warehouse system, pallet, trolley for input materials: chair frame, foam, seat cover, sensor, air bag, seat belt, assembly accessories, plastic sheet, hand handle, lift ...

- 3 assembly lines for seat models with different configurations. Each line includes:

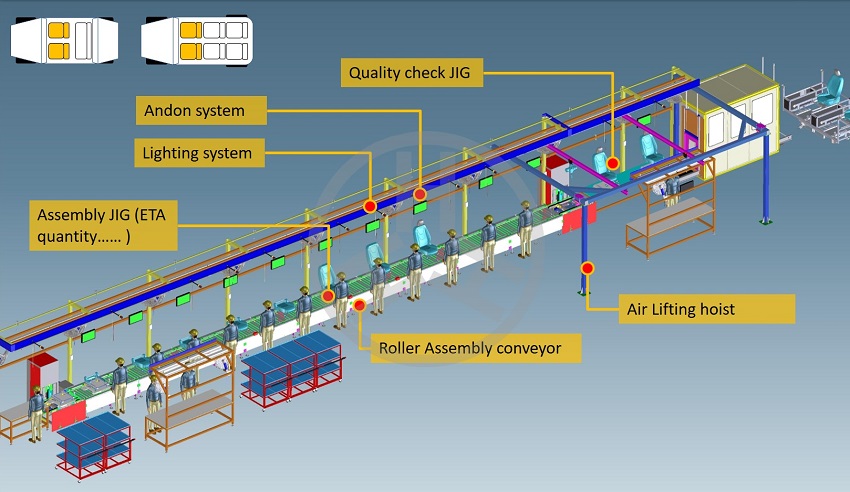

+ Structure, lighting, fan, power supply, water, compressed air, boiler, steam iron ... tool holder: barcode reader, C-ring gun, gun air ... .Push buttons and stage indicators, incident lights, Andon lights ...

+ The assembly conveyor through stages (2 PVC belt and 1 roller conveyor) with the assembled jig moved and returned automatically through 50 stages of seat assembly by experienced engineers. We built and optimize for customers.

+ Systems of jig, assembly jigs, check for each stage: cover, airbag, seat belt, gap ...

+ Repairing table for NG products at the lines

+ Sub-assembly table

+ Barcode system print/read codes for air bags and components for assembly of PMS connection

Connecting factory MES system, production management system, torque tester, screw and bolt forgetting control. Control over shortage of accessories and QC for assembly quality at each stage. Andon and Pokayoke systems manage data for the whole line. Real time management. Production status with LCD screen, production digital board.

- Test area for assembled products at the end of the lines

- Noise testing room

- Warehouse for finished products, shelves system, finished product trolleys.

Steps to implement car seat assembly line project

Design, manufacture at CNC-VINA

Machining at CNC-VINA factory with: assemblies, paint, inspection works:

+ 3D and 2D design, machining drawing

+ CNC machining, welding, painting and assembling assemblies, factory inspection

+ Order standard equipment

Installation at the customer's factory in stages

+ Installation of structure lines, auxiliary systems: electricity, water, compressed air, signals, lights ...

+ Installation of conveyors

+ Installation of noise testing room, lifting system

+ Installation of warehouse shelves

+ Installation of jig, jigs, equipment

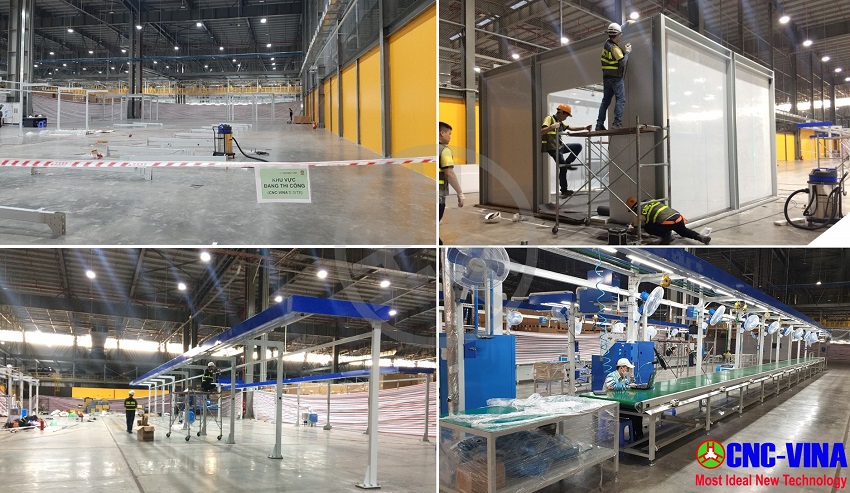

Some photos of the construction and installation of automotive seat assembly lines at the customer's factory.

Programming, commissioning and system connection

+ Programming PLC system

+ Programming, commissioning and connecting the production management system

The process of commissioning and testing is carried out in parallel with the installation of each item, ready to connect the entire line.

With 13 years of experience in the automation industry for the auto-motorcycle industry FDI customers, CNC-VINA confidently provides customers with assembly-inspection lines, umbrella assembly lines. professional automotive, car painting lines and turnkey projects.

Find out more of our products below and get in touch for support:

Motorbikes assembly factory lines

Quality inspection line for motorbike

Automated printer assembly line with robots

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Factory: Song Cung industrial site, Dong Thap commune, Dan Phuong district, City. Hanoi Vietnam

Phone: +84.915 74 4 664 / +84.915. 74 0880

Website: www.cncvina.com.vn; www.maytudong.com.vn; www.cncvina.net

Email: Sales01@cncvina.com.vn | Sales03@cncvina.com.vn

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese