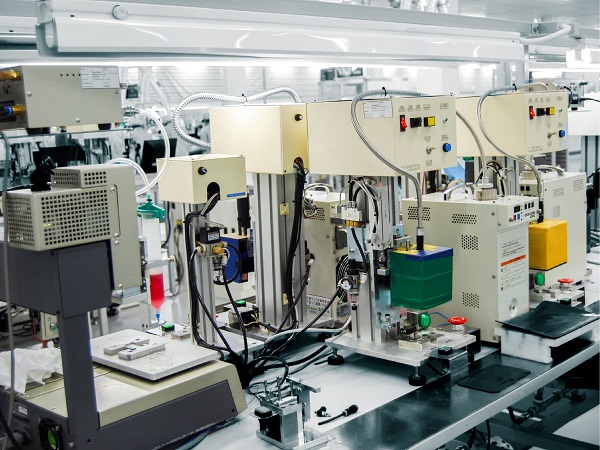

UV and ultraviolet projectors drying glue board machine

Application of UV projector and ultraviolet projectors drying glue board machine

Automatic UV projectors are one of the assembly machines used extensively for loudspeaker assembly lines, electronic circuit boards. The machine is designed to perform the drying of the glue on the board by projecting the UV light onto the adhesive surface. This stage takes place after the glue injection and assembly stage joins the layers together, the glue is sealed on the board.

UV projector is designed compact, automatic and safe operation. Customer-tailored design with each component assembly request on the circuit board, in the assembly line. The design is flexibly customized thanks to changing the programming and jigs, parts jig for each product and the purpose of use. Design customer-required machines for electronic components assembly lines for mobile phones, computers, televisions, …

Technical specifications of UV projector and ultraviolet projectors drying glue board machine

UV projector in electronic components assembly line has a compact, simple design.

Programmed to operate automatically and safely for users.

Structure and principles of operation

The UV projector is designed and manufactured by CNC according to customer requirements.

However, basically, the machine is composed of the following main clusters:

- Machine frame structure is assembled from shaped aluminum. The machined aluminum plate ensures the rigidity and weight reduction. Helps easily move and setup at locations in assembly line in customer factory.

- Jigs, jig for flexible parts designed to fasten the parts that need to be dried quickly. Help replace the jigs and parts easily, save time but still ensure accuracy.

- Ultraviolet ray head assembly (UV light), which controls hardening UV rays at the locations to be Fix. UV ray assembly performs fast and safe drying of the glue.

UV rays (also known as ultraviolet rays, ultraviolet rays) are very harmful to human skin and eyes. So the UV projector on the machine is designed to ensure separation and safety for the machine operator.Operate ultraviolet glue dryer (UV rays).

The operation of the glue feeder, glue applicator and glue drying machine for component board is simple and easy. Workers carried out parts that were applied with glue and need to be dried in jigs designed and processed according to each product. And press the button to operate. UV drying irradiation chamber with active protection cover will radiate ultraviolet rays and dry the adhesive film. At the end of the drying process, the dry glue layer ensures bonding. The product is taken out to the next stage. With each request to seal adhesive film or seal components together, customers can choose to use automatic glue machine, UV projector. Or use a 2-in-1 machine for glue and UV light projection at the same time.

Loudspeaker assembly line for mobile phones, electronic components assembly combined with automatic robot system, product-level conveyor, helps the assembly process to be automated, stable operation, and follow flow with the highest productivity. Bring the highest profit to customers.

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese