Production management system

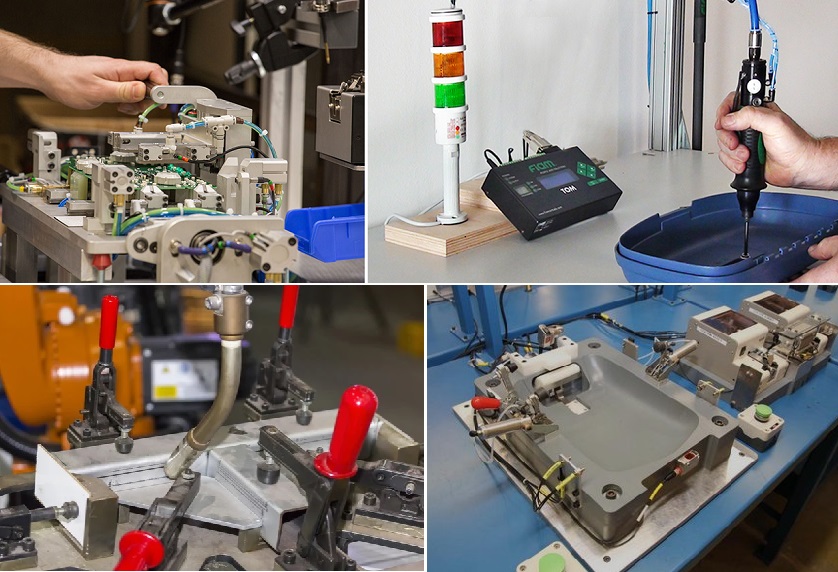

The production management system updates in real time with solutions from Andon, Poka-yoke, MES systems that control the actual state of the production, helping the material flow to take place continuously. Ensuring to avoid undue mistakes and mistakes that affect the product quality and production progress of the line.

Comprehensive production management solution for smart factory and manufacturing enterprise provided by CNC-VINA. Interested customers please contact us for advice and support:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Hotline: 0915744664 | 0915740880

Email: Sales01@cncvina.com.vn | Sales03@cncvina.com.vn

Production management system and production solutions CNC-VINA provides for customer factory lines including: factory production management system, product quality management by barcode, management board production, output boards, jigs, stage inspection jigs, push buttons, indicator lights, production management software, assembly, testing, Andon systems, Pokayoke, MES ... Applications for manufacturing industries mechanical, electronic assembly, automotive & motorbike, garment ...

What is the production management system?

Production management is a stage of production and business activities of factories and enterprises; participate directly in the planning, monitoring the progress of the production process to ensure the supply of goods that meet the correct quantity and meet the quality of the output criteria built from the top table. plan.

The production management process in an enterprise consists of 4 main stages:

- Assessment of production capacity

- Plan material demand

- Management of production stages

- Product quality management

With the traditional production management, the organization model and production management in the enterprise mainly attach importance to and focus on the human factor with:

Management department

Main production department

Auxiliary production department

Sub-production team

Team for production

Today, with the development of science, technology, and technology, and increasingly demanding in the management of production and assembly lines to optimize productivity and improve quality, while minimizing costs and labor force, production management system was born and increasingly help people in smart factories in the task of managing production with accuracy, reliability, timeliness and flexibility.

A modern production management system is a combination of one or more software that manages all stages and an entire line.

Effective production management methods include intelligent factory management and manufacturing solutions, and the software meets requirements such as:

- Production operations according to customer orders (MTO: Make To Order)

- Configure production monitoring and management to order (CTO)

- Assemble To Order (ATO: Assemble To Order)

- Fabrication to order (ETO)

- Manufacturing according to warehouse needs (MTS: Make To Stock)

- Material Requirement Planning (MRP: Material Requirement Planning)

- ANDON system: a tool to detect anomalies in the production process, then immediately notify by sound, video to a group of people in charge of an abnormal area.

- Poka-Yoke system helps detect, prevent and fix errors

- Lean production, production execution system, factory operation (MES: Manufacturing execution system)

- Master data management (MDM: Master Data Management)

- Product life cycle management (PLM: Product Life-cycle Management)

- Monitor productivity, monitor progress, monitor online production output (wired, wireless wireless). Real-time monitoring of the production process with intuitive display parameters on electronic boards, production boards. The parameters include number of input products, outputs, NG, countdown time of the project ...

Current production management systems

Depending on the complexity of production activities and the management requirements of the business, the production management system will be of different scale. Accordingly, customers can use different softwares for monitoring and managing production activities.

Below are production management solutions that are commonly used in production lines, assemblies, and factories in Vietnam.

LED Production Display Boards

Production management is the process of managing and updating the parameters of production, production progress and making counterparts in order to achieve set production targets and plans.

Table of production monitoring, output, productivity, production progress led boards are located at the production lines, stages in the assembly line to help visualize the parameters of product output ( reality / target), productivity, NG ratio, target time ... help managers easily grasp the status of the line and make changes (if necessary) soon.

Specifically: The table shows the output value set for each shift and the actual output value up to the present time. Helping production managers and workers know their performance, to adjust production progress accordingly. Help manage the output remotely using LAN or internet.

Instantly and visually display ANDON (Call for Help, Delivery Call, Abnormal Device) at each position on the line. All information is saved as a database for reporting and printing.

Led display board for import and export management:

- The led displays board detailed information about priority order, vehicle codes being received and preparing to receive traffic

- Adjust data manually, by computer or by remote control.

- Data management software can save product information and give results daily, weekly and monthly reports.

- Using stable hardware with high processing speed and flexible software. Real-time management system and computer connection to exchange information and data for the manager.

Led board monitoring parameters of the production, import-export process is usually an LED board with stable operation with high durability. Some production lines also use production boards that are LCD screens and TVs for flexible changing requirements.

Output board, production control display: plan, target, actual, display system according to requirements indoors and outdoors

Production management system with ANDON

Andon production management system is a tool to detect abnormalities in the production process, then immediately notify by sound (horn, bell, speaker), picture (lamp, production board, monitor picture) to the group of people in charge of an area that has abnormalities thanks to push buttons, switches, selection feature on the error screen ...

Andon system allows employees or equipment to activate the production warning system when it detects an abnormality, sending notice of immediate action (repair, maintenance, material supply, ...). Based on the signal sent by the Andon system, the production operator dispatches the right people to assist.

The Andon System comes in many forms: from warning of a production location of a process like a production machine to warning for multiple stages and lines. From simple light / bell alarms to complex panels. A common feature of all types is the production alert system of real-time production status in the monitored area.

Role of the Andon system in production:

- Immediately warning of unusual problems, need help when they happen in the production process.

- Provide a simple and consistent mechanism for the communication of information on the plant floor between the operator and the management and maintenance team.

- Encourage immediate response to quality, downtime and safety issues.

- Increase operator accountability by increasing their accountability for “good” production and empowering them to take action when problems arise.

- Enhances the ability of the supervisor to quickly identify and resolve production problems.

- Extend the life of equipment and machinery

- Andon system also prevents defective products from reaching customers, and at the same time, avoids mass defects on many products.

- The support person recognizes the problem, they know exactly which area to go to and what to solve the problem, saving time on troubleshooting.

However, the Andon system does not have a self-fix mechanism, it is only an announcement and needs to be interacted with other relevant parts such as maintenance, raw materials, QC department, etc. … In order to avoid these messages in the next operation shift forcing the relevant part to remedy.

Production management system with POKA-YOKE

Poka-Yoke is a tool to help detect errors and problems. Poka-Yoke helps prevent mistakes or prevent mistakes. It was developed by management consultant Shigeo Shingo as part of the Toyota production system.

Poka-Yoke ensures that the right conditions exist before a process step is executed and thus prevents errors from occurring in the first place.

Its purpose is to eliminate product failures by preventing, correcting or attracting human attention when they occur.

Application example Poka-Yoke

In a broader sense, it is also a constraint that shapes behavior as a process step to prevent failure.

One of the most common is when the driver of a car with a manual transmission has to press on the clutch pedal (one handling step - Poka-Yoke) before starting the engine. The interlock prevents the vehicle from moving unintentionally.

Another example is a car with an automatic transmission, which has a switch that requires the car to be in the "P" or "N" state before it can start.

These are the constraints that shape the behavior because there are actions that must be performed before the vehicle is allowed to start. In this way, over time, the driver's behavior is adjusted as required by repetition and habit.

Other examples can be found in childproof electrical outlets or the washing machine does not start if the door is not closed properly to prevent flooding. These types of automation do not allow errors or incorrect operation in the first place.

The role of the Poka-yoke system in production

The production management system with Poka-Yoke can be used whenever something goes wrong or something goes wrong - literally everywhere. It can be successfully applied to any type of process in the manufacturing, assembly or service industries, preventing all types of errors:

- Error handling: A procedure operation was omitted or not performed according to a standard operating procedure.

- Setting error: Misuse of tool or incorrect machine adjustment setting.

- Lack of accessories: Not all parts are included in assembly, welding or other processes.

- Inappropriate part / item: The part is incorrectly used in the process.

- Operation error: Perform an incorrect operation; There are incorrect versions of specifications.

- Measurement error: Error in machine adjustment, check measurement or part size comes from the supplier.

Poka-Yoke is easy to do because of its universal and rational nature.

In a production process, the appearance of technical defects, defects leading to defective products is inevitable, while humans cannot control all. At this time, the anti-error tool will be applied to promptly detect errors, notify people, to have the fastest remedy.

When an error occurs, the Poka-Yoke tool will automatically disconnect the working system, and at the same time notify the relevant person. The timely detection of faults and breakdowns prevents defective products, at the same time minimizes costs of damage and warranty.

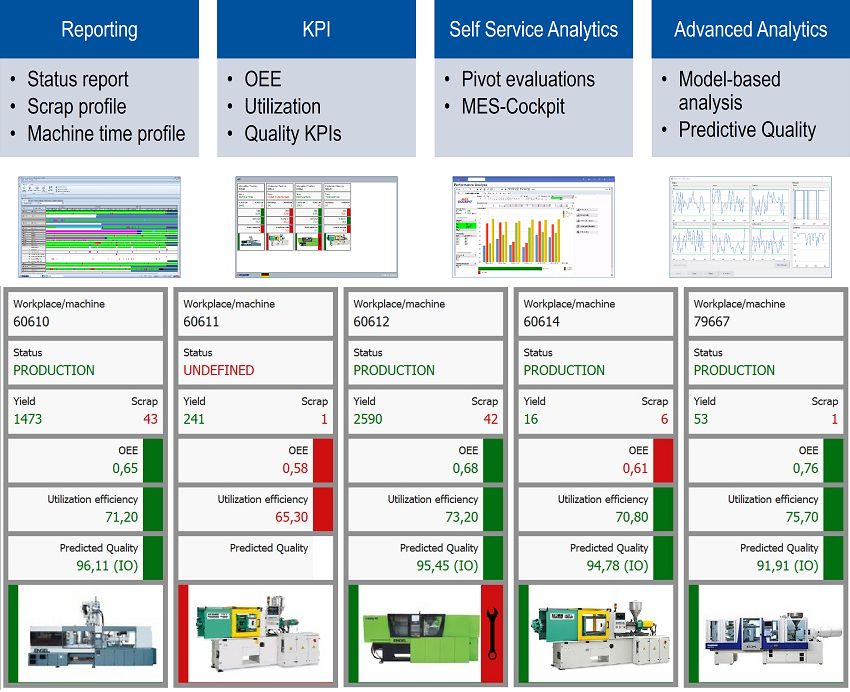

MES production management system

Manufacturing Execution System (MES) is a computer system with specialized software and equipment used in manufacturing and assembling factories to track and record the transition from raw materials, for sale. finished products to finished products.

MES provides information to help plant and plant decision-makers understand how to optimize current conditions on the plant floor to improve production output.

MES works in real time to allow control of many elements of the manufacturing process (e.g. inputs, personnel, machinery and support services). MedIDs can operate across a wide range of areas: managing product lifecycle product definitions, resource planning, fulfillment and ordering, production analysis and downtime management to achieve performance. equipment's overall results (OEE), product quality or tracking of materials and tracks. MedID creates a record of data, processes, and results of the manufacturing process. This can be particularly important in regulated industries, such as electronic assembly, food and beverage or pharmaceuticals, where documentation and evidence of processes, events and events may be required. act.

Manufacturing Execution Systems help create flawless manufacturing processes and provide real-time feedback on request changes, and provide information at a single source. Other benefits from a successful MES implementation may include:

Reduced waste, reproduction and scrap, including faster setup times.

Get a more accurate capture of cost information (e.g. labor, scrap, downtime and tools)

Increase uptime

Incorporate paperless workflow activities

Traceability of production activities

Reduce downtime and find errors easily

Reduce inventory, through the elimination of matching inventory.

With intelligent production management system and many features. The parameters of the production, assembly, and inspection lines will always be updated and controlled. Help managers quickly grasp the status of projects and come up with appropriate solutions, solutions and handling. Ensure the progress of the project.

Customers who are interested in and wishing to build, plan and install a production management system for their factory line please contact us for advice and support:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Factory: Song Cung industrial site, Dong Thap commune, Dan Phuong district, City. Hanoi Vietnam

Phone: +84.915 74 4664 / +84.915 74 0880 Fax: +84.24.37805007

Website: www.cncvina.com.vn; www.maytudong.com.vn; www.cncvina.net

Email: Sales01@cncvina.com.vn / Sales03@cncvina.com.vn

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese