Automated vertical warehouse VLM

Automated warehouse-Vertical lift machine smart warehouse is a module smart warehouse solution developed by CNC-VINA and provided to customers with the motto of bringing benefits to Vietnamese customers using technology products, saving up to 30%.

CNC-VINA automated warehouse helps to save space, time and improve warehouse exploitation efficiency. The product is fully machined, installed and programmed in Vietnam to help reduce costs significantly and shorten installation time as well as easy operation, maintenance and maintenance.

Contact us for advice on automated warehouse solutions, smart warehouses and automation solutions for smart factory, please contact:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Hotline: 0915744664/0915740880

Email: Sales01@cncvina.com.vn / Sales03@cncvina.com.

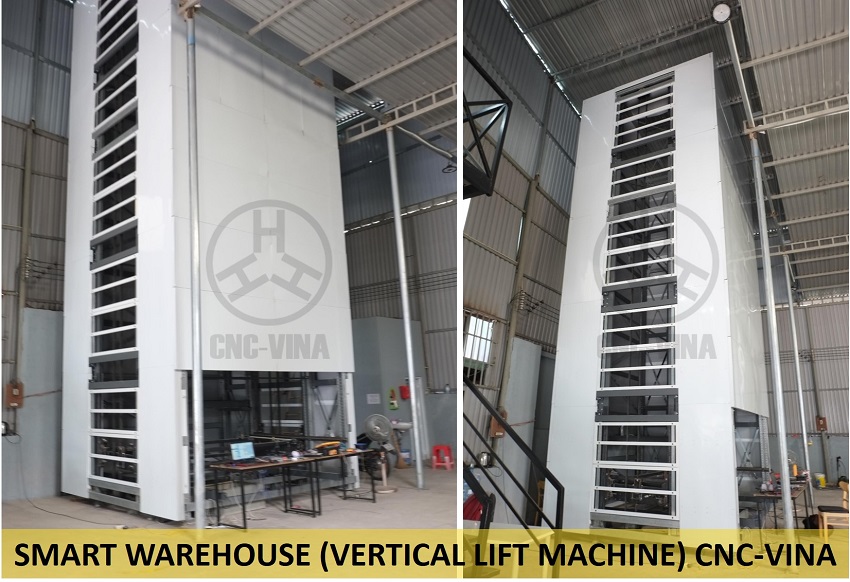

The first Automated vertical warehouse (Vertical Lift Machine) in Vietnam is developed and provided to customers by leading experts in the field of module smart warehouse solutions from CNC-VINA.

Smart vertical warehouse is the ideal solution for industrial factories, electronic components assembly, medical equipment and supplies, logistic warehouse, e-commerce, post center. distribution, postage...in order to save storage area by taking advantage of the maximum height of the warehouse ceiling by the method of goods to person.

[toc heading_levels="1,2,3,4"]

Learn about automated warehouse - Vertical Lift Machine CNC-VINA

The product is researched and developed with the goal of bringing European technology, smart warehouse management facilities and science and technology with affordable investment costs for Vietnamese and FDI enterprises in Vietnam. .

In the past, European modular warehouse solutions were known for their optimization and undisputed benefits, but the investment was quite high, often beyond the capabilities of businesses. Now, with the same technology, our vertical module automatic warehouse products are manufactured in Vietnam with the same features that will give customers the highest benefits with the most reasonable cost.

Why should invest in vertical warehouse made in Vietnam?

Customers can use European technology products with affordable Vietnamese investment costs

Automated vertical warehouse with the entire structure is domestically manufactured and assembled according to the design of safety and optimization. Helps reduce leading time and cost significantly compared to having to import from abroad to assemble. The motors and the controller for the module are fabricated and assembled according to the standards built by CNC-VINA, which can be flexibly customized according to customer requirements. Warehouse management software WMS with friendly, easy to use Vietnamese / English / Japanese interface..

A team of experienced Vietnamese engineers and warehouse experts. Customers always receive prompt and professional support. The costs of importing goods, costs for foreign technicians and experts are cut down to cost by more than 30%, giving our products a competitive advantage.

Customers can now significantly benefit from using European quality and technology smart warehouse products at the Vietnamese prices.

Outstanding advantages of vertical automated warehouse compared to traditional warehouse

As its name, the automatic warehouse product developed by CNC-VINA maximizes the advantage of vertical storage capacity.

Space saving

That is with a limited floor area –foot print normally just enough to install rack warehouse systems with a height of only 3-4m (the current situation of many customer), it is now possible to install automated warehouses. Modular form up to 10m, making the most of the factory height. Goods are stored (from) and retrieved (to) the underground warehouse manager location with just a few mouse clicks on the control screen.

The automatic vertical warehouse is a box-type warehouse that saves space in the floor space. Increase productivity up to 3.5 times compared to a static solution. Save warehouse space from 70% to 90% by making the most of the ceiling height.

The tray load is up to 250kg with the product height up to 800mm.

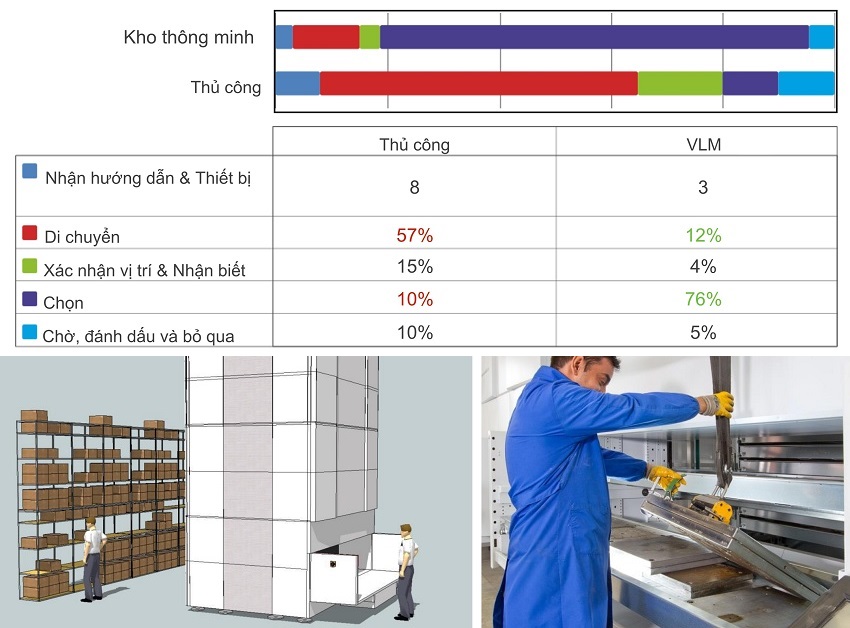

Time saving

The height 0.8m ~ 1.2m from the ground to the place of placing and receiving goods makes handling easy and safe for users. The external station supports lifting large or heavy items and the use of hand assistants with heavy loads reduces moving time.

Instead of having to bring the product to the specified position, just click the empty tray order and place the product in the tray right in front of you. The rest is the calculation software and the lifting system.

Furthermore, the connection with the warehouse software WMS (Warehouse Management System) helps to access real-time data. Inventory management is easier than ever. No more time will be wasted on finding supplies and goods in stock. Especially long distances in the warehouse to search and pick up goods are completely gone because the automatic vertical warehouse will bring the goods to your location with just one click on the control screen.

There is no need to remember and check which goods are located where to pick up because the smart warehouse has a spatial optimization algorithm that sorts the goods into the position with the best free space for the goods.

Especially, with the new warehouse manager, you no longer need to get used to locations, package names, shelves, floors, warehouse floors, product areas A, B, C ... A task that takes a lot of time, space in traditional warehouse solutions.

Risk reduction

Automated vertical warehouse with sweeping safety curtain system is installed behind the location of each receiving compartment for product height measurement, protecting users.

The emergency stop button on the dashboard is more secure

Identify the product over height to ensure the safety of the warehouse. Avoid damaging the product.

The weight measurement system of the storage tray ensures the load capacity of the tray and the storage module

Maximize travel speed by tray load with electronic scales.

Increased security

Increase protection with a completely enclosed storage system.

Increase efficiency and safety for the operator.

Automated warehouse with high security: Password is required to access

Various levels of access with different permissions: Operator-Supervisor (Higher level than operator) -Support (Maintenance and installation) -Customize restriction- Full protection - Access for each individual tray.

Important documents, important products will not be afraid of being released out or into the hands of unauthorized people.

Improved accuracy

With the declared product codes, the software storage system will identify and store for immediate retrieval and ordering of goods. Fully automatic inventory update.

Improve inventory management with smart warehouse management software

Improved tracking capabilities.

Complete control over inventory data

Manage and arrange static and dynamic archives

User-friendly interface.

Ability to integrate with any ERP system

Full traceability.

Suitable for integration with existing inventory software systems.

Specifications refer to CNC-VINA vertical warehouse

Height from 4.0m to 10.0m depending on workshop height and customer investment cost. Of course, the higher the warehouse height, the higher the efficiency of the warehouse operation, the more customers will benefit from this automated storage solution.

Tray Size 0.8 × 3.0x0.12m (there is an optional box compartment in the tray with the purpose of storing small items according to customer requirements.

The load capacity of each tray is 250 kg

Load capacity of the machine (may vary depending on the number of trays placed inside the machine): 15 tons: 60 trays, 0.25m tray spacing (standard)

Total machine capacity achieved: 23 tons. (tray + row)

tray = K = const (120kg), cargo = H (<250kg) m. (K + H) = <23 tons,

Maximum product height stored: 0.8m (may vary depending on the number of trays placed inside the machine):

Productivity (throughput): 36s / cycle (highest tray intake 9.5m)

Dynamic storage of the trays: depending on specific height

The vertical shaft lift design is controlled by a chain lift system on both sides of the machine body.

Vertical Lifting System: Extractor with 8 rollers for each side of the lift.

Measure the tray weight automatically each time the tray returns using the loadcell.

Galvanized iron structure is designed and machined domestically.

Application of the Smart warehouse Vertical lift machine

Automated vertical warehouse is used in most industries of manufacturing, manufacturing, assembling, garment, logistics, and storage, bringing high efficiency to warehouse operations.

Application of vertical module smart warehouse:

Automotive industry: Storage of assembly spare parts, equipment, semi-finished products, electronic accessories, sensors, buttons ...

Mechanical & supporting industry: Storage of semi-finished products, tools, supplies, spare parts, molds, equipment, finished products, processing parts for export

Electrical / electronic industry: components, electronic accessories, circuit boards, chips, hard drives, ram, monitors, telephone components, television sets, PCB assemblies, finished electrical equipment

Garment / apparel - shoes & bag industry: Save rolls of fabric, raw materials: buttons, threads, buttons ..., accessories, spare parts, materials, machines, molds.

Pharmaceutical & medical equipment: Raw materials, finished products, equipment, medical supplies, test samples, medical records, drug distribution centers, cosmetics, production formulas ...

Logistics and e-commerce: Storage center combined with product and goods classification line by conveyor

Government institutions, banks, administrative agencies: Records & documents.

And others.

A smart automated warehouse or a vertical module smart warehouse will help you maximize the usability of the warehouse system and easily manage the storage and import of your goods. Smart modular warehouse, smart pallet warehouse with collaborative robot, palletizing robot, AGV with warehouse management software, loading / unloading system, industrial conveyor belt has been and will be important components. indispensable importance of smart factories in modern production.

Customers who have demand for smart warehouse solutions and automation solutions for smart factory please contact:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Factory: Song Cung industrial site, Dong Thap commune, Dan Phuong district, City. Hanoi Vietnam

Phone: +84.915 74 4664 / +84.915 74 0880 Fax: +84.24.37805007

Website: www.cncvina.com.vn; www.maytudong.com.vn; www.cncvina.net

Email: Sales01@cncvina.com.vn / Sales03@cncvina.com.vn

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese