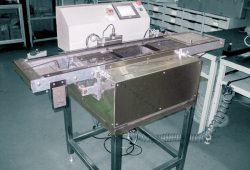

Automatic bottle capping machine

Application of automatic bottle capping machine

Automatic bottle capping machine is widely applied in large-scale manufacturing enterprises because it has high performance, increased productivity and labor efficiency.

For a long time, the industry of producing food, cosmetics, water and liquid bottles has grown very well with large and diverse designs. Plastic and glass bottles / jars such as beverages, food or pharmaceuticals and cosmetics … all need to use automatic or manual bottle cap fasteners.

Structure of automatic bottle capping machine

Automatic bottle capping machine consists of 4 main parts:

- Division of decentralization

- Conveyor system

- Vortex screw cap structure

- Movement structure.

Each department is in charge of its own functions but still ensures coordination to bring the best performance.

Principle of operation

Principle of operation and operation of automatic bottle capping machine are as follows

Bottle capping machine automatically operates via PLC control screen.

The machine is connected to 220V power.

Set the bottle cap spin mode.

The stopper will be adjusted via the feature button on the device.

The machine operates continuously with the pre-set mode.

Working performance of automatic bottle capping machine

Automatic bottle capping machine is a specialized automatic machine, fully automatic operation based on the pre-set system. Therefore, screwing the cap does not need as many workers to join as the traditional assembly method.

It operates 24/7 continuously, bringing high productivity in a short time. In contrast, manual bottle cap fasteners with performance depend entirely on the operator.

The benefits of automatic bottle capping machines.

Automatic bottle capping machine is one of the automatic machines that apply the most advanced and modern technology today. Therefore, it possesses many outstanding advantages so it is very popular. It contributes to reducing the time and effort of the assembly industry in the beverage, food and cosmetic industries to produce the market with a fully automated solution. Food safety and hygenic.

Currently, all kinds of automatic bottle capping machines have been one of the automatic solutions to help save the best costs for food and chemical production and business units. The machine is modernly designed, combining many features of many modern industrial machines such as bottle washing machine, bottle extraction and bottle capping machine, bottle filling and capping machine, machine for bottle capping and closing technology. automatic bottle, bottle capping system, cooking oil bottle capping machine, drinking water bottle, plastic bottle stopper, glass bottle capping machine. All integrated in a complete machine with the most common name today is the versatile automatic bottle capping machine.

The machine operates fully automatically with high output, nice design, durable operation. Help save production investment costs, increase production profits, increase product efficiency and quality to help businesses lower costs and production costs, improve competitiveness.

Customers interested in and need to order automatic bottle capping machine, please contact Hotline: 0915744664 | Email: Sales01@cncvina.com.vn for advice and support.

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese