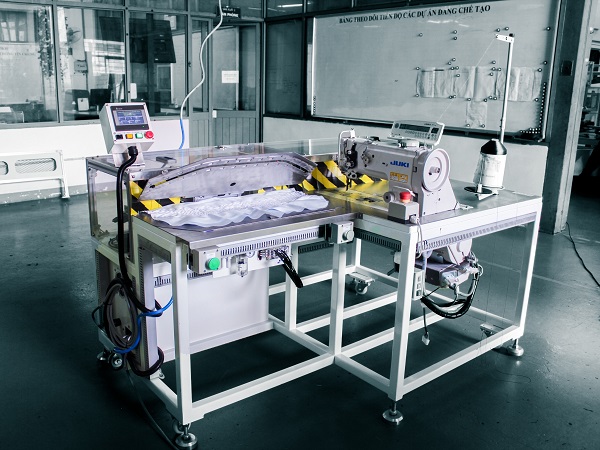

Automatic sewing machine No.2 (200x700)

Application of Automatic sewing machine, automatically open Jig:

Automatic sewing machine (XY sewing machine) NO.2 (200 × 700) is a specialized automatic machine designed and fabricated by CNCVina according to customer requirements according to specific products in the industry garment.

The machine is programmed in the X and Y directions according to each specific product type (easily changing different product models) to bring efficiency, to increase productivity, reduce labor capacity compared to manual methods.

The machine is widely used in industrial garment factories.

Technical parameters of automatic sewing machine open Jig

- Machine size: W x L x H = 1150 x 1780 x1100 (mm).

- Operating height: 810mm from floor surface.

- Main power source: 1 phase source. AC 200V / 50Hz

- Electrical control: DC 24V

- Air supply source: 0.4-0.6 Mpa

- Has a warning feature when pressing the Start button that the Jig has not closed yet

Structure of CNC-VINA’s automatic sewing machine

The construction of automatic jig sewing machine includes:

+ Cluster of upper and lower sewing machine frames

+ Japanese industrial sewing machine JUKI brand

+ Cluster of Jig

+ X / Y 2-way movement structure using ball screw, high precision guide rail TBI, PMI, HIWIN (or optional). Servo, encoder Delta.

+ Control panel, PLC programming display and operation on Delta screen control panel.

+ Cover cluster helps to protect sewing machine from external impacts.

Outstanding features and operating principles and operation of automatic sewing machines

Automatic sewing machine is one of the most commonly used automatic sewing machines. Products designed and manufactured by CNCVina with outstanding features can sew both ways at the same time. With different product models, customers can easily switch by selecting the program for that model and replacing Jig (with product positioning structure, clamping according to the form to sew) respectively. Automatic sewing machine can be operated simply and quickly.

The operating principle of the automatic opening of the sewing machine Jig is that the sewing process simultaneously in both X and Y directions occurs automatically creating the desired seam.

Operation is very simple and safe for workers:

+ Workers put the sewing product into the correct pin latch position.

+ Click Start Jig automatically press down on the product and run according to the programmed program.

+ The machine finishes sewing and automatically cuts the thread and automatically runs to the original position and automatically opens the Jig.

+ Workers take finished products out of Jig.

+ Repeat process for the next product.

Pictures of trial garments on CNCVina’s automatic sewing machines before installation for customers

Note when installing and supplying electricity and pneumatic for sewing machines

When installing, always make sure to align the elevation and balance of the machine surface.

Power supply: Before supplying power to the system to check the safety of the electrical system: electric cabinet of sewing machine, wiring system, power source ... Main power supply 1P - AC 200V - 1.5 KVA - 50Hz. DC 24V control power supply (Electrical diagram, see also attached Power and Electrical drawing section compiled by CNCVina’s engineer).

Supplying air to the system: Connect the quick-pipe plant air supply line to Regularor in two positions.

Maintenance and maintenance process

Always clean the machine after every shift

Check the machinery, electrical and pneumatic systems of the machine before each shift

Before carrying out maintenance of the sewing machine, the machine must be brought to the original point, disconnecting all electricity and then carrying out maintenance.

Compliance with maintenance and maintenance requirements and operations for mechanical systems, movement structures and electrical systems.

Looking for a supplier of automatic sewing machines and sewing lines?

Vietnam's textile and garment industry is a key industry in the economic structure. In 2013, Vietnamese textile products exported to more than 180 countries and territories with export turnover of US $ 17.9 billion; accounting for 13.6% of Vietnam's total export turnover and 10.5% of the country's GDP. In 2018, garment export turnover reached US $ 28.78 billion, up 14.45% and always tends to increase next year. So the garment processing market is a very attractive investment field.

With the development of the automation machine industry and the application of automated production lines, domestic garment enterprises want to maintain production and improve their competitiveness, investment in machinery and modern lines are essential.

CNCVina with many years of experience in the automation industry and supporting textile and mechanical industry is a reliable choice for customers. We always offer optimal solutions to ensure technical requirements, productivity and minimize investment costs of customers. Customers are interested and need to invest in automatic sewing machines, industrial sewing lines and automatic machines upon request, please contact for advice and support:

VIETNAM TECHNOLOGY & CNC APPLICATION JOINT STOCK COMPANY

Factory: Song Cung Industrial Zone, Dong Thap Commune, Dan Phuong District, Hanoi City, Vietnam.

Phone: 0915744664

Website: www.cncvina.com.vn; www.maytudong.com.vn; www.cncvina.net

Email: Sales01@cncvina.com.vn

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese