Automotive painting line

Automotive painting line and total solution for paint line in the factory have been and are being provided by CNC-VINA to customers in Vietnam. Paint line is designed, fabricated, installed and operated with modern technology, reasonable investment cost and environmentally friendly to help bring customer satisfaction.

With the cooperation with paint experts from the world’s leading paint line brands and domestic automobile factories, we will surely bring customers modern and effective technology solutions. fruit.

Interested customers please contact us for advice and support:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Hotline: 0915744664 | 0915740880

Email: Sales01@cncvina.com.vn | Sales03@cncvina.com.vn

Automotive painting line is one of the important lines of automotive production and assembly factories. Along with the hull welding line, assembly line, investing in domestic car painting line, the localization rate of Vietnamese automobile manufacturers has been improved, gradually mastering the technology and mastering the assembly and production process.

CNC-VINA is a supplier of ED paint line, powder coating, plastic coating with extensive experience in automotive and motorcycle painting. We specialize in consulting, designing, supplying, installing paint workshop lines for factories manufacturing and assembling cars, manufacturing components, motorbike spare parts and industrial equipment. Applying modern, self-contained, automatic ED coating and electrostatic paint technology to bring high productivity and friendly environment.

Paint solutions provided by CNC-VINA have been promoting efficiency, bringing the highest benefits to customers with the most optimal investment costs.

Why should we choose CNC-VINA as a partner to design, manufacture and install automotive paint lines in Vietnam?

The cost of an imported car painting line is usually high

One of the top priorities of customers who are planning to invest in a car painting line is investment cost. Normally, the investment cost of painting lines will be quite high if foreign car paint partners are selected. The large cost, in addition to the reason for the brainpower and modern technology, is also due to the costs of the experts (accommodation, work, training, operation, maintenance ...), the cost of imported equipment and materials, customs procedures, transportation ... If choosing domestic contractors to cooperate, the costs will be cut significantly.

CNC-VINA brings paint technology from the world's leading painters to customers

Automotive paint lines are designed in cooperation between CNC-VINA and the world's leading automotive painters from Germany, Japan, Korea, Malaysia, China, paint experts. long-time working in paint workshops from automobile and motorcycle factories in Vietnam. Customers can be completely assured of paint technology, installation quality, training and maintenance services from domestic suppliers.

Significantly reduce the cost of materials for the installation of the paint line if choosing a local supplier

All structures fabricated and installed by CNC-VINA-domestic supplier will help customers get benefits in terms of cost and investment costs. CNC-VINA in particular and the structural manufacturing units, the installation of paint lines in general have the machining, fabrication and installation quality that are not inferior to the foreign units.

Materials, materials and processing costs, labor costs, installation labor are available at much lower prices than foreign partners. The contractor installing the domestic painting line is completely active in processing, manufacturing and installing, regardless of the time of import or transportation.

Paint line installation progress is always guaranteed

In addition to proactive reasons for outsourcing, manufacturing and installation personnel to help customers benefit in investment costs, our experienced paint experts are assigned to specialized in professional work. assigned items. The ability to interact with customers and solve problems at the site quickly and flexibly. Helps ensure the progress of system installation and operation.

Technical and safety requirements are always followed to minimize incidents affecting the progress of the project.

Be proactive in operation, maintenance and maintenance

With a team of maintenance and maintenance of ancillary systems, experienced paint technology lines and paint experts from Vietnam and abroad, personnel working at the paint lines of customers will be trained and directed. Full and detailed instructions for precise, stable and safe line operation. We also share new technologies and experience during operation to help customers improve paint productivity and work safety.

With the selection of a paint line installation unit in Vietnam, customers will always receive the assistance of a paint specialist in the shortest and fastest time.

Basic process of an automobile painting line

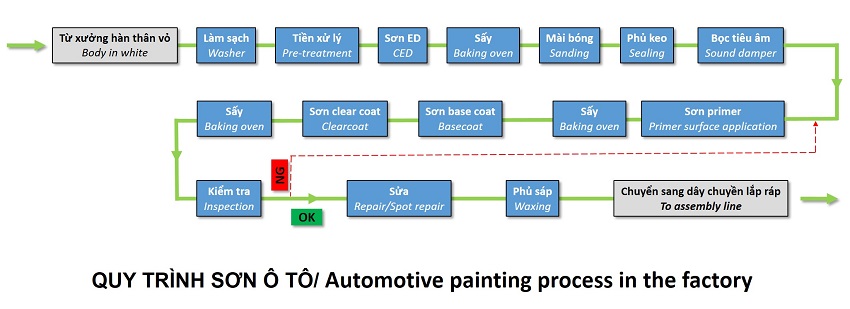

Painting a car is not as easy as you would find the staff members at the garage you used to be. You can't just grab a brush and scrub the surface and start painting your car. You have to prepare and carry out a lot of steps before you start painting your car. We will talk about all the steps required to paint a car. Of course, depending on how paint companies' paint process is built and paint requirements, capacity, vehicle model number and level of automation of customers, some stages in the paint line may be combed. remove or combine in other stages, or add. Accordingly, the backend systems can be simplified. But basically the painting process includes the following steps:

The chassis goes through the Pre-Treatment line and is painted with ED paint (E-coat)

The process of cleaning and painting ED is carried out by a system of steel tanks, stainless steel tanks with a volume of several tens to several hundred m3 / tank-PT&ED line has a circulating pump system to filter paint and control the specifications.

The first station in the painting process is the pretreatment, where the tires that pass through the paint shop are cleaned, heated, degreased and often phosphate on the surface in preparation for the next coating. The second step of the process is electrostatic-ED coating, which is coated with a corrosion-resistant primer by immersing the tank in a conductive tank. To ensure that the interior is also properly disposed of, the trunk is soaked during the process.

Here, the frame from the hull welding workshop moves on a dolly or transverse chain conveyor, the conveyor that attaches the hull jig is brought into position in front of the line, grabbed by a crane system and dipped through the tank or item the mounting on the conveyor belt rotates 180 degrees to dip the tire into the tank. During all stages of the paint line, the body is placed on the trolley-attached fixtures on the propeller rail or programmed floor conveyor or hanger conveyor.

Traditional ED coating technology has been used in the automotive industry for many years with FRP-coated dipping tanks and anode electrode plates. The pre-treatment and electrostatic coating technology with Ecopaint WetSystem is based on the advanced and flexible technology being applied by Durr, a German car paint company, for new automotive paint lines.

Painting a car requires a suitable environment, free of ambient dust and high humidity. Chemical tanks, DI water always need to be controlled with indicators of temperature, humidity, bacteria, PH ... to ensure the best ED paint.

The layer of ED paint for car chassis is the coating that determines the durability of the bodywork. During use, the decorative paint you see on the outside can be scratched, destroying the interior frame. If the ED painting process is not good, vehicle structure will be affected, causing unsafety during use. This is not allowed. It protects the vehicle from corrosion, especially the body cavities which cannot be easily accessed by the spray paint method.

Furthermore, the quality of ED paint affecting the painting process of Primer and Top Coat will be discussed below.

Dry the ED paint in the oven

Electrostatic ED coating on the car body after coming out of the paint tank is dried ED in the Oven hot air oven can be up to 150 degrees Celsius. control by vehicle model. Oven is powered by a heating system - a gas or oil burner. At the end of the oven, there is a fan cooling system to help reduce the body temperature before going to the next stage.

Polishing, filling pump for undercarriage, sound absorption

In this stage, unsatisfactory paints will be polished by sanding machines in the polishing room. Next, the car body will be taken to the sealing area, sealant and sprayed PVC undercarriage, sound damper before going to the next stage.

Paint primer and top coat in paint booths and dry in the oven

These are spray painting stages in spray painting where temperature, humidity, and light are controlled. Paint by human or robotic arms with the aid of mixing systems, paint dusting, air conditioning systems, ventilation ...

Primer Paint Primer paint smooths the existing surface of the ED primer coat, protects the primer primer against rust and and increases the adhesion between coats, helping to detect any substrate irregularities and possibly sanded easily.

Paint Top coat with a basecoat and clearcoat painting stage. These two painting steps are basically the same, only differ in technical requirements due to the use of the substrate and the outer coating. After each stage is finished, the tires are put into the oven at high temperature before moving to the next stage. Top coat painting usually has 2 stages: base coat and clear coat.

Base coat: gives the main color to the body of the car, so it plays an important role in making the visual impression on customers.

Clear coat: painted at the end. It protects the car from external factors such as rain, sun, snow, UV radiation, dust ...

Repairs may be interwoven in the surrounding work zone cubicle areas.

Refer to the thickness of the layers of paint (human hair is 0.1 millimeters = 100 µm)

ED: 17-22 µm

Primer: 30-35 µm

Basecoat: 10-20 µm

Clearcoat 30-50 µm

Inspection, Repair, Wax, Spot repair before moving to the assembly line.

Inspection, Repair, Wax, Spot repair - These are the final stages of the automotive coating line. Currently, this stage is still mainly using humans with the help of equipment or collaborative robots.

In addition, the automobile and motorcycle manufacturing and assembling factories may have more plastic paint lines to help paint plastic details and bumper for complete vehicle assembly.

The systems and equipment in the car painting line

Car painting line is a sequential line requiring each stage to always ensure quality so as not to affect the next stage. Therefore, in addition to the main system, the backend system also plays a very important role in the chain.

Systems and equipment in the automotive painting line include:

Coating system PT-ED. Oil tanks, tanks, chemicals, paint dipping tanks...

DI, RO water supply system, hot water supply Boiler, cooling chiller, wastewater treatment system, weekly pump system, UF filter system...

Plastic coating system

Conveyor systems, Conveyor systems, lifting systems (hoist, cranes)

Oven after each painting step. Combustion chamber system with gas burner, burner oil burner for fuel from oil station, LPG station.

Paint booth. Fresh air supply system for chain (ASU, AHU) and air conditioning, temperature and pressure balance. Paint dust stamping system, paint residue treatment.

Mixing automatic paint mixing system: 1 color, 2 colors, 5 colors... and painting equipment.

Paint removal system, line, JIG...

Area of spraying, polishing and repairing chambers (Work zone)

Fire fighting system, compressed air, water supply, electrodynamic system, lighting ...

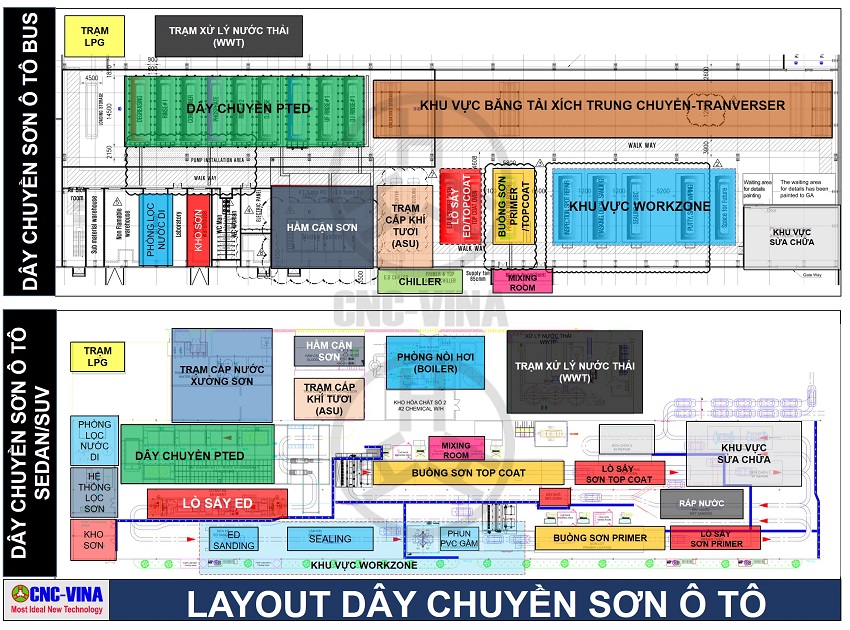

Depending on the plan and design, the painting line can be arranged in stages on the plan lying next to each other or parallel, or according to the basement-floor-floors.

CNC-VINA provides customers with painting lines for cars, motorbikes, painting products on request with modern paint technology and optimal investment. Customers interested in painting line products please contact us for advice and support:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Factory: Song Cung industrial site, Dong Thap ward, Dan Phuong district, Hanoi city, Vietnam.

Phone: +84.24.37805173 (74) Fax: +84.24.37805007

Hotline: +84 915744664

Website: www.cncvina.com.vn

Email: Sales01@cncvina.com.vn

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese