Industrial manipulator

Industrial manipulator – solution to support lifting in assembly lines, processing machines and lifting goods. The air balaman lift arm developed by CNC-VINA creates flexibility in clamping, grabbing, lifting, rotating and reciprocating movement to ensure accuracy and simplicity in each operation.

Contributing to minimizing human effort in the lifting and lowering stage and ensuring labor safety in production.

The fixed column support arm, fixed suspension, mobile suspension meets loads up to 2000kg. The design can be customized according to customer requirements.

Contact us immediately for advice on lifting solutions suitable for your products:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Hotline: 0915744664 | 0915740880

Email: Sales01@cncvina.com.vn | Sales03@cncvina.com.vn

Manipulator is one of the popular industrial lifting manipulators used in manufacturing plants, assembly lines and inspection today. Pneumatic or electric, and sometimes hydraulic, Manipulators (for large lifting loads in tons) help operators pick and lift objects and products of large sizes and volumes with safety. high, improve working efficiency. In contrast to vertical lifting aids (cranes, hoists, etc.) fabrication and assembly, inspection.

On the market, there are 3 popular types of manipulators using power sources: electric, pneumatic, hydraulic with different names. But the most popular is the pneumatic balaman-handling air manipulator type capable of lifting loads from 50kg-100kg. This power arm series is suitable for products of assembly and processing lines such as: motorcycles, mopeds, electric scooters, e-scooters, car engines, car seats, tires and windshields, car door, structural assembly, motor, motor reducer, compressor block...

[toc heading_levels="1,2,3,4"]

The custom designed pneumatic balaman arm allows the operator to float and manipulate the product easily without the need for a power source. Simply connect to a compressed air source and the machine is ready to go.

[caption id="attachment_3889" align="aligncenter" width="660"] canh tay tro luc tay nang tro luc manipulator CNC-VINA[/caption]

canh tay tro luc tay nang tro luc manipulator CNC-VINA[/caption]

The unique design of the controller with the air cylinder retains the special features of the electric powered lifting device but at a more economical price. It also allows for more freedom in mobility. Standard models will be capable of lifting loads up to 2000 kg. With custom-designed CNC-VINA lifters, the industrial manipulator allows for virtually no weight restrictions.

The available compressed air source is utilized, bringing efficiency and safety in operation, making the industrial lifting manipulator using pneumatic balaman/industrial handling air manipulator more and more popular. Bringing benefits to reduce labor force, improve working efficiency and ensure labor safety.

Manipulator models designed and manufactured by CNC-VINA

CNC-VINA researches, designs, manufactures and markets all kinds of pneumatic powered lifts. CNC-VINA power arm has 4 standard types:

Please click on each product at the end of the article to see detailed specifications.

Industrial manipulator with load capacity of 60kg/100kg/200kg/500kg/1000kg...column MF series- (Fixed Manipulator).

Industrial manipulator with load capacity of 100kg/200kg/500kg/1000kg/2000kg...column MFF Series- (Flexible Fixed Manipulator).

Industrial manipulator with load capacity of 100kg/500kg/1000kg/2000kg...Mo series fixed suspension (Overhead Manipulator).

Industrial manipulator with load capacity of 100kg/200kg/500kg/1000kg/2000kg... mobile suspension MRO Series (Running Overhead Manipulator).

[caption id="attachment_3863" align="aligncenter" width="650"] tay nang tro luc manipulator CNC-VINA[/caption]

tay nang tro luc manipulator CNC-VINA[/caption]

In addition, the manipulator has moving wheels for the needs of lifting and lowering loads (but the range of movement will also be limited due to the included air supply line). This type is mainly used for assembly, tire repair, small engine lifting and cargo handling.

The column-type handling air manipulator (MF/MFF Series) fixed on the workshop floor thanks to bolts has the following advantages: Simple, convenient, easy to use and has wide application, high safety.

However, there are disadvantages: it takes up space for the position of the column to be mounted, and hinders travel in the area where the column is fixed on the floor.

The fixed pneumatic-air industrial manipulator (MO Series) has the advantages of saving space and wide operating area. However, the disadvantage is that the installation requires high safety, the cost is often higher than the column lift model with the same load.

Pneumatic powered manipulators moving overhead rails in the X/Y direction (MRO Series) are similar to crane lifting systems with the following advantages: large working space, flexibility and convenience. The lifting arm can be moved to any position under the truss to pick up and move objects or tools for assembly. However, the disadvantage is the need for the accompanying structural system, the installation time is longer and the cost is higher than the fixed type.

Depending on the load and the needs of the customer, the design team of CNC-VINA will advise and choose the appropriate solution for using the industrial manipulator. The standard power assisted models we provide are suitable for products weighing from 50kg-2000kg with diverse applications in today's processing, assembly, manufacturing, and logistics factories.

Specifications of CNC-VINA Air manipulator provided

|

Spec./Model |

MF Series |

MF Series |

MF Series |

MF Series |

|

Dimesion |

3200mm(L) x2500mm(H) |

3300mm(L) x2500mm(H) |

3300mm(L) x2000mm(H) |

5000mm(L) x5000mm(W) x3500mm(H) |

|

Travel |

X3000mm / Y3000mm |

|||

|

Height lifting |

1200mm |

1200mm |

1200mm |

1200mm |

|

Radia rotation |

3000mm |

3000mm |

3000mm |

3000mm |

|

Max load |

60/100/200/ 500/1000kg |

100/500/ 1000/2000kg |

100/500/ 1000/2000kg |

100/200/500/ 1000/2000kg |

|

Air Pressure |

Max 0.7MPa |

Max 0.7MPa |

Max 0.7MPa |

Max 0.7MPa |

Note: The parameters in the data sheet are for reference only for the lowest load models. Various types of Manipulatorwith loads will be designed and manufactured by CNC-VINA depending on customers' requirements and products. Please contact us for advice, design suitable models.

CNC-VINA provides customers with 4 standard Manipulator models for products up to 100kg. Depending on the needs of the customer, we will design and choose a solution suitable for higher loads such as 200kg/500kg/1 ton/2 ton/5 ton…using a high capacity powered hand lift with Solid structure and safety factor are calculated on specialized 3D software.

With different lifting products, the clamping, gripping, and suction head will be different. We assist customers in designing and processing clamps for each specific product.

With optimized design, easy mounting and replacement, all your products are guaranteed to be safe during travel with our lifting and clamping heads.

Advantages of CNC-VINA pneumatic manipulator arms

The air - balaman uses an energy source entirely by compressed air, which is economical available in the factory. Most factories need compressed air to use for processing and assembly machines and have compressed air pipelines with silos on the line. It is very easy and convenient to extract air supply to the power-assisted hand cylinder.

When lifting the load, if there is a problem of loss of gas supply (pressure drop), the system will lock out of work, completely unaffected and the load will not fall in the case of clamping. The load is in a suspended state, any operation to release the load, open the clamp has no effect. Ensure the safety of the user and the goods being hung on the balaman.

In case the gas pressure is less than 0.4 Mpa, not enough working pressure, the system will automatically stop working.

When there are many different weight variations of the product to be handled; Regardless of product weight variation, pneumatic lifting cylinders handle variable loads without adjustment.

The lifting and moving of the load is entirely controlled by the operator's arm navigation. That is, when lifting and moving, we only need to navigate the operation from how the hand puts the load to the position we want. When clamping and when sucking, both use the control buttons on the hand tool.

The gas powered arm is an easy to install, low maintenance system. Box steel structure, welded steel plate with anti-rust paint, paint finish for high durability. Swivel joints use precision, sealed bearings that provide long life and smooth movement that are easy to maintain.

Advantages that Manipulator brings

+ Helps lift gently, not only lifting, when lifting, you can still rotate and flip the lifting object as you like. The movement of up and down, in and out, 360 degrees of rotation, slanting or wriggling over obstacles is much more flexible than with other lifting devices.

+ Absolutely safe when lifting heavy objects. The emergency braking system ensures that there is no free fall or non-directional rotation of the product. Ensure the safety of workers and goods.

+ Reduce labor. With a powered lifter, a person can lift objects up to 100kg and more to a certain height without exerting effort to rotate and hold each time the lever is moved.

+ Control at will precisely.

+ Increase labor productivity. With repetitive moving stages, lifting and moving are performed continuously for outstanding high productivity.

+ Use in all environments with toxic and dangerous substances...With chemical products that cause irritation when in direct contact, high temperature metal products from forging, casting, stamping machines, the use The manipulator will make loading/unloading jobs easy and safe for the operator as well as the product and surrounding machinery.

Easy to use just by connecting to a compressed air source, no worries about the trouble of fire, short circuit, oil leakage. Anyone, whether a woman or an elderly person, can operate this Manipulator with ease.

Applications of manipulator CNC-VINA

The air manipulator of the robot arm that controls the lifting and lowering has the main function of picking, lifting, and moving (according to rotation, vertical and horizontal translation) to bring the object and product to be lifted from the original position. to the next position of a stage in the production or assembly line. Or simply arrange bulk objects with the fewest people and fastest.

Below are the applications of the lifting arm in industry:

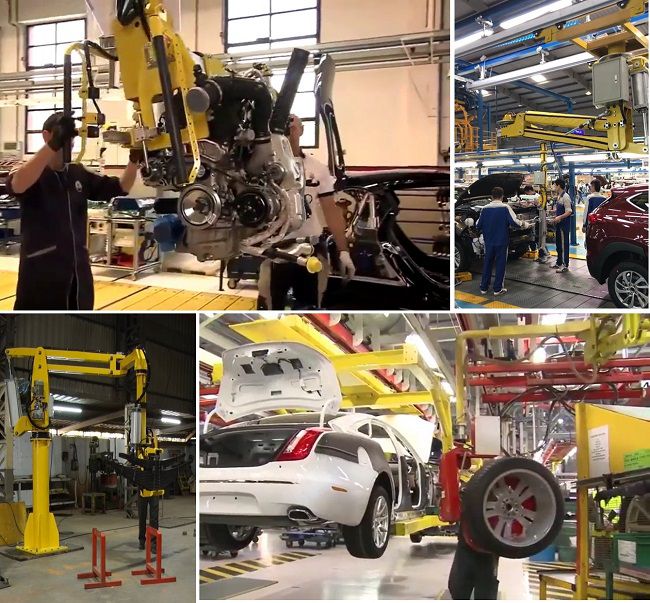

Balaman, manipulator for lifting and lowering in automobile and motorcycle assembly line.

In the motorcycle assembly line, the Manipulatoris usually placed at the end stages of the line. When the weight of the vehicle has been assembled, the equipment is almost complete (usually less than 100kg).

[caption id="attachment_3864" align="aligncenter" width="650"] tay nang tro luc manipulator lap rap o to[/caption]

tay nang tro luc manipulator lap rap o to[/caption]

At these positions of the line, the weight of the vehicle is quite high, if using human power to lift the product to install it on the assembly machines, it will be very laborious and unsafe. Moreover, the fact that the product has to move continuously, changing the position of operation on the vehicle with workers standing outside the line requires the lifting mechanism to be really flexible.

The Manipulator meets the above requirements when it can easily support people with the following operations: grip, fix, grab, rotate, lift, move, rotate, translate, brake, release the product. accurate and safe products.

Unlike motorcycle assembly, car assembly lines require more than heavy lifting equipment and manipulators. Because in addition to the chassis and bodywork, other parts weighing several tens of kilograms to 100 kilograms are also difficult for workers.

The pneumatic balaman can support assembly workers for the assembly stages of seats, engines, powertrains, steering systems, and tires. Using the industrial-industrial manipulator in the form of columns (Column) installed on the factory floor, fixed form (Fixed), fixed hanging form (Overhead) or mobile hanging in the X/Y direction (Running Overhead) helps The assembly process is much more flexible and safer.

Installing windshields for cars is also one of the stages that need the participation and helpful support of this hand balaman. The tongs of the power arm are equipped with a glass suction cluster to help the glass plate be lifted with an even suction force, easy to move and rotate the angle according to the operator's wishes, accurately assembled with only 1 operator. This pneumatic power steering arm is also widely used for processing tempered glass, safety glass, ordinary glass and wood panels, large plastic sheets, cartons...

Industrial manipulator for loading and unloading goods

One of the interesting applications of industrial lifting manipulators today is loading and unloading goods at manufacturing plants, especially in the import and export department. Imagine if your products weighing 60-100kg are mass-produced and are gathered at a location waiting to be moved (into the warehouse or on a truck to the customer's factory).

[caption id="attachment_3865" align="aligncenter" width="650"] canh tay tro luc xep do hang hoa[/caption]

canh tay tro luc xep do hang hoa[/caption]

Or when importing products such as electric motors, speed reducers, machine oil cans, chemicals, oil drums.. for production. The use of many people carrying or forklifts, forklifts, cranes is clearly not the optimal solution in terms of manpower, safety and time.

With industrial-hand balaman. You can handle them alone with these simple arm operations: Pick up the trailer, put it on the truck, put it in the seat inside the car, lower the goods from the truck to the ground easily, fast and safe.

The handling air manipulator works really well without being affected much, whether the operator is a woman, an elderly person or a person with not too good health.

Hand balaman lifting equipment is suitable for most bales, wooden pallets, plastic, cartons, machines with crane hooks, cans, crates, drums, glass panels, billets, sheet metal materials, rolls Embryo, …

Handling air manipulator for feeding workpieces for machining machines

One of the other useful uses of the industrial manipulator is to feed the workpiece to the machine and move the finished product out of the machine (Loading/Unloading, Pick and Place).

With the mechanical processing of products of medium to large size and weight, the stage of putting the workpiece on the machine table for checking and bringing the product out after processing is a laborious and potentially dangerous step. to the machine operator.

The Manipulator helps to pick up heavy weight plate workpieces from the gathering position outside the machine (using hand-lifting magnets, electromagnets, clamps) to the mounting position in the machine room. With the degrees of freedom on the joints of the power arm, the workpiece can be moved easily in many directions, directions and heights without the limitations as with cranes, cranes or conventional chain hoists. In particular, the industrial manipulator is capable of moving and manipulating very flexibly in narrow spaces and many obstacles.

With stamping, forging, metal casting machines... the products that come out of the processing machine have a large weight, high temperature and are very unsafe for the operator if rudimentary tools are used. Hand Balaman helps to pick up and take the product out of the machine easily and absolutely safely. The lifting arm is also used to lift and move long pipes to the position of saws and cutters.

[caption id="attachment_3866" align="aligncenter" width="650"] Tay nang tro luc cap phoi may gia cong[/caption]

Tay nang tro luc cap phoi may gia cong[/caption]

For products that go through many stages, the power lifter is ideal for transferring products between machining operations, saving workers time and effort.

The power lifter in general and the pneumatic powered lifter in particular are useful assistive arms with easy control operation just by connecting to a compressed air source.

Using pneumatic power steering is safe, no worries about fire and explosion problems caused by electric shock, oil leakage. Save energy and economy with assembly lines.

Customers are interested in and need to design and manufacture assembly machines, power lifters, industrial manipulator arms, balaman, air balancers for the automotive industry, motorcycles and assembly lines, control tra Please contact CNC-VINA for support:

VIETNAM CNC & TECHNOLOGY APPLICATION JOINT STOCK COMPANY

Factory: Song Cung Industrial Site, Dong Thap Commune, Dan Phuong District, City. Hanoi Vietnam

Phone: +84,915 744 664 / +84,915. 740 880

Website: www.cncvina.com.vn ; www.cncvina.net

Email: Sales01@cncvina.com.vn | Sales02@cncvina.com.vn

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese