Paint shop line

Paint shop line for factories manufacturing and assembling cars and motorcycles usually includes paint lines with ED coating technology (for metal frames and bodies) and plastic paints (for parts cover) , coveralls, outer cover with plastic material). CNC-VINA is a unit with extensive experience in projects of design, installation, renovation of paint and painting lines for large customers in Vietnam.

The common feature of our paint line projects is always to meet: the complexity of the system, the high technical and professional requirements as well as the progress of the investor. Always providing optimal solutions in design and manufacturing to help save investment costs of customers and ensure the efficiency and stable operation of the line when put into operation and use.

Paint workshop line is one of the factory chain systems that are being paid attention by many customers, when Vietnam's manufacturing, assembling and supporting industries and industries have been officially entered a new page after the emergence and rapid development of names like VINFAST, MAZDA TRUONG HAI, HYUNDAI THANH CONG.

CNC-Vina is the total solution provider for the paint workshop line, the technology of car and motorbike paint, provided with the form The key to turn-turn key projects, including: Design master plan of paint line. Supplying equipment, manufacturing and installing electrostatic dip coating line (electrophoresis ED) according to customers' requirements (UF filter equipment, pumps, pipes, washing hoses, jacuzzi hose.

New installation and renovation of the entire system, paint workshop line and auxiliary systems for paint workshops, including:

PT-ED paint line system Plastic paint system UF filter filtration system

DI water filtration system according to the required capacity.

Conveyor system, conveyor chain (conveyor), lifting system (hoist, cranes)

Combustion system with combustion chamber, combustion chamber, oven for ED coating, primer, top coat (base coat + clear coat)

Fresh air supply system for line (ASU-Air Supply Unit) and air conditioning, temperature and pressure balance for kiln system, paint chamber (AHU-Air Handling Unit)

Chiller system for cold water cooling for PT, ED, AHU tanks

Boiler hot water supply system Tank, tank of oil tank, chemical storage tank, paint dip tank...

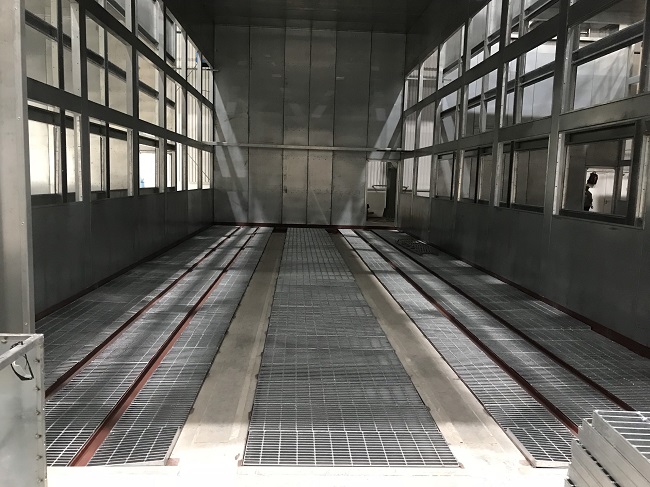

Structure of tunnel, floor, kiln of paint line 1-color, 2-colors, 5-colors automatic paint mixing system and paint equipment.

System, paint removal line, burning JIG...

System of firefighting, compressed air, water supply, paint treatment...

Training, use, maintenance of items and the entire paint workshop for customers.

Training and operating the kiln system, combustion chamber, UF, DI system

Training of paint processes, spraying of PVC glue, sanding, wet grinding, polishing, product inspection

Training, operation, maintenance of tunnels, kilns, dust suppression systems, conveyor chains...

Some pictures of paint workshop lines of customers

The entire system of paint lines is using high quality components from countries with the leading automotive industry: USA, Germany, UK, Japan, imported synchronously with very competitive prices. . We have been providing a lot of projects of designing, installing, improving ED coating system, motorcycle plastic paint for many big customers in Vietnam such as: YAMAHA, GENERAL MOTORS VIETNAM, VINFAST ,. . and receive trust and appreciation from customers. Interested customers please contact us for advice and support:

VIETNAM TECHNOLOGY & CNC APPLICATION JOINT STOCK COMPANY

Factory: Song Cung Industrial Zone, Dong Thap Commune, Dan Phuong District, Hanoi City, Vietnam.

Phone: +84.24.37805173 (74) Fax: +84.24.37805007

Hotline: +84 915744664

Website: www.cncvina.com.vn; wwww.maytudong.com.vn

Email: Sales01@cncvina.com.vn

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese