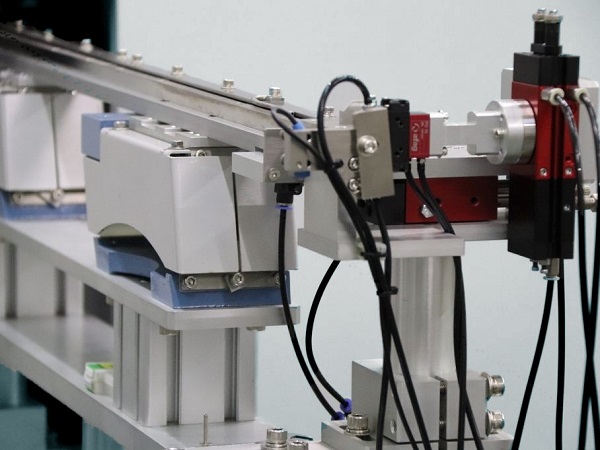

Vibrating linear feeder

The vibrating linear feeder, also known as the linear vibrating feeder, the linear feeder, the linear work-piece … is a mechanical device that can transport materials, parts, and products. Taken from the vibrating plate, the bowl vibrates in a straight line. Application products include small parts: springs, screws, bolts, washers, electronic and medical components, … Billet vibrators are combined with vibrating funnels and structures. another to create automatic billet delivery system is very popular in assembly lines and inspection.

With modules designed and made into each block, flexible length of 100 ~ 1,000 mm as required, the vibrator bar is easily coupled in a straight line without any distance. Automatic billet vibrator products are designed and fabricated in combination with vibrating hoppers according to specific products depending on customer requirements. Hotline: 0915744664.

Principle of vibrating linear feeder

- Common linear linear loaders consist of three parts: linear groove, electromagnet and spring piece.

- The electromagnet is vibrated by connecting the electromagnet to a 220v AC voltage and the electromagnet controls the linear orbit through the spring to achieve the goal of straight line parts.

Application of linear vibration bars

Linear feeder is used in a wide range of applications. In general, the vibrating linear feeder is necessary for part transport requirements on the straight line in the line. Application products include mechanical engineering, machine parts, electronic components, medical ...

Feature of linear loader:

- It consists of tracking and vibrating devices, and is mainly used with vibration plates.

- The work-piece is moved smoothly and neatly.

- Can transfer work-pieces to a long distance.

- Convenient installation and easy connection with other devices in your automatic line.

- Improve the productivity of the part movement from the rear hopper by automatically and keep the direction and direction of the product accurate. Combined with the stop sensor, break the hopper vibrating when there is a problem to help the system operate reliably and stably.

OUR PARTNERS

English

English Vietnamese

Vietnamese Japanese

Japanese